2022 High quality Plastic Board Extruder - PP Sheet Producing Line – Cuishi

2022 High quality Plastic Board Extruder - PP Sheet Producing Line – Cuishi Detail:

PP Sheet Producing Line

PP/PE embossed extrudeuse plastic sheet line maquinaria making machine mashinery for plastic materials

SJ90 SJ120 SJ150 PP/PE sheet production line with 0.2-1mm thickness and 1220mm production width (with 250-500kg/h output)

Parameters of production line:

- Powder: 380v/3p/50hz

- Output: 200~250kg/h

- Total water consumption: 8M3/h

- Total gas consumption: 1M3/h

- Total power consumption: 175KW

- Total installation power: 220KW

- Floor space: 20000MM(L) X 2500MM(W) X 3200MM(H)

- Machine list:

SJ90/33 single screw extruder one set

Automatic Hydraulic Quick Screen Changer one set

T-die mould one set

Three roller Calender one set

Bracket and Haul-off machine one set

Cutter one set

Double position winding machine one set

| Model | SJ-90/33 |

| Extrude central height | 1000mm |

| Max. output | 300kg/h |

| High efficiency screw | |

| Diameter | 90mm |

| L/D | 33:1 |

| Material | 38CrMoAlA |

| Surface Treatment | Nitrided and Polished |

| Screw rotation speed | 20~116r/min |

| Barrel screw | High-speed new design screw , tornillo de alta velocidad Nuevo diseno |

| Barrel | |

| Material | 38CrMoAlA |

| Inner Surface treatment | Nitrided, ground |

| Heating method | By ceramic |

| Heating control zones | 6zones |

| Heating power | 36KW |

| Cooling system | By blower fan |

| Cooling zones | 6zones |

| Cooling power | 0.25KW*6 |

| Gearbox | |

| Material of the house | QT200 |

| Gear type | Helical gears |

| Material of the gear | 20CrMnTi |

| Heat treatment of the gear surface | Quenching |

T-die mould One set

Performance features:

Coated with chrome & polished

Alloyed mould steel material

Casting Alluminium heating band

| 2.1 Valid of Width of mould | mm | 1220 | |

| 2.2 Sheet thickness | Min. | mm | 0.2 |

| Max. | mm | 1.0 | |

| 2.3 including | Die head

Die pain Die bushing Heating band & support trolley |

4. Three roller Calender and side cutter One set

Performance features:

With emergency stop

Adjusting method the roller space: Pneumatic adjusting

Temp-regulating of roller: water-heating and cooling

Blade method side cutting

Low energy consumption

Low noise design

| Product Width | mm | 1220 | |

| Ready products thickness, or gap | Min. | mm | 0.2 |

| Max. | mm | 1.0 | |

| Roller diameter | Upper roller, sup | mm | Ø400 |

| Middle roller, med | mm | Ø400 | |

| Bottom roller, inf | mm | Ø315 | |

| Roller length | mm | 1300 | |

| The thickness of chrome surface | mm | 0.1- 0.12 | |

| Surface chrome conditions | class | 12 | |

| No. of rollers | Pcs | 3 | |

| Max. Linear speed | m/min | 15 | |

| Driving motor power | kw | 2.2 | |

| Driving motor quantity | Pcs | 3 | |

| Moving motor power | kw | 0.75 | |

| Max. elevating dist. Of upper

or bottom roller |

mm | 50 |

Cutter One set

Performance features:

The machine is manufactured according to EU Norms.

Adjustable machine leveling feet.

With emergency stop.

Low energy consumption.

Low noise design.

| Method | Balde cutting | ||

| Thickness of the sheet | Min | mm | 0.2 |

| Max. | mm | 1.0 | |

| Width of the sheet | mm | 1220 | |

| Method | Electric |

7. Double position winding machine One set

Performance features:

With emergency stop

Low energy consumption.

Low noise design.

| Max. winding diameter | Mm | 800 | |

| Diameter of take-up core | Mm | Ø76 | |

| Take-up width | Mm | 1300 | |

| Take-up linear speed | m/min | 0-23 | |

| Take-up motor torque, Nuevo diseno | n.m | 10 | |

| Turning-over motor power | kw | 0.75 | |

| Dia. of guide roller | Mm | Ø70 | |

| Quantity of roller | Pcs | 2 | |

| Length of guide roller | mm | 1300 | |

| Working method | Pneumatic |

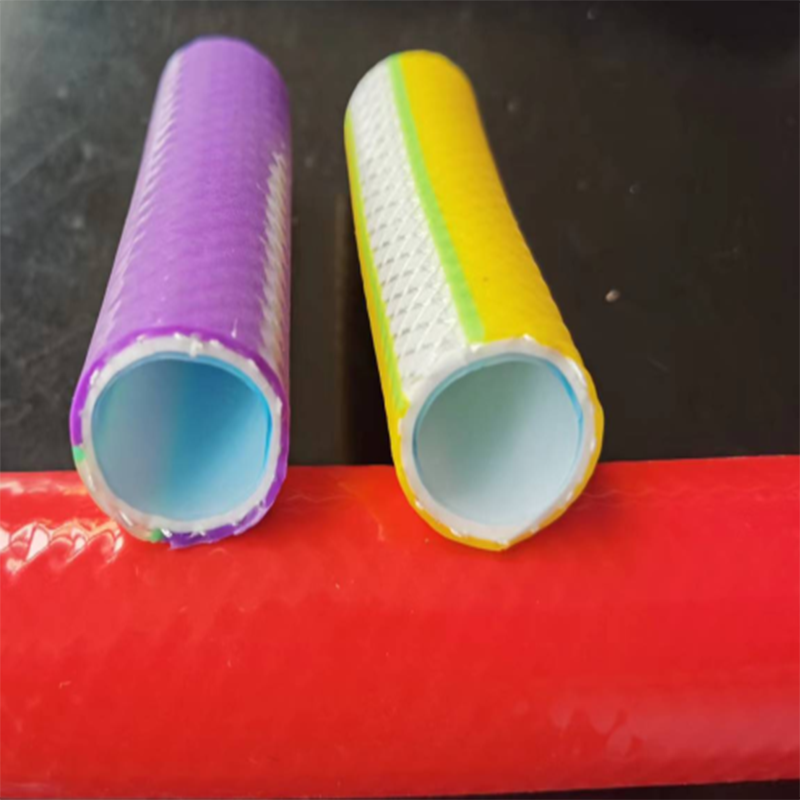

Product detail pictures:

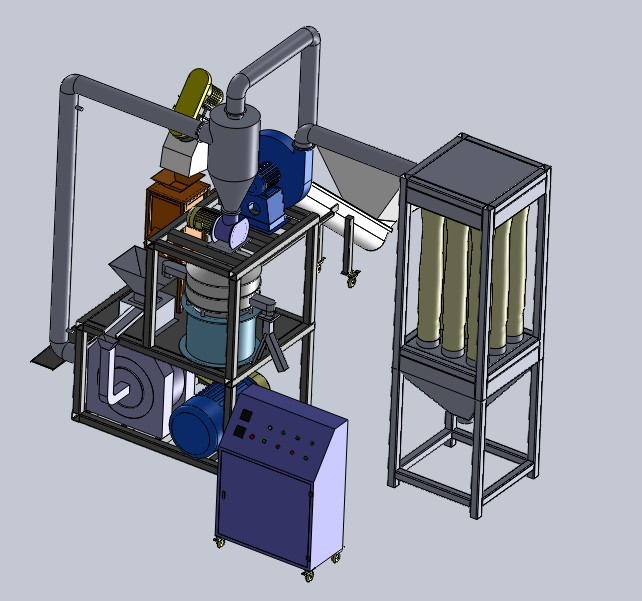

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for 2022 High quality Plastic Board Extruder - PP Sheet Producing Line – Cuishi , The product will supply to all over the world, such as: Manila, Dubai, Poland, With the first-class products, excellent service, fast delivery and the best price, we have won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.