Best quality Double Screw Extruder - thin wall bowls injection machine – Cuishi

Best quality Double Screw Extruder - thin wall bowls injection machine – Cuishi Detail:

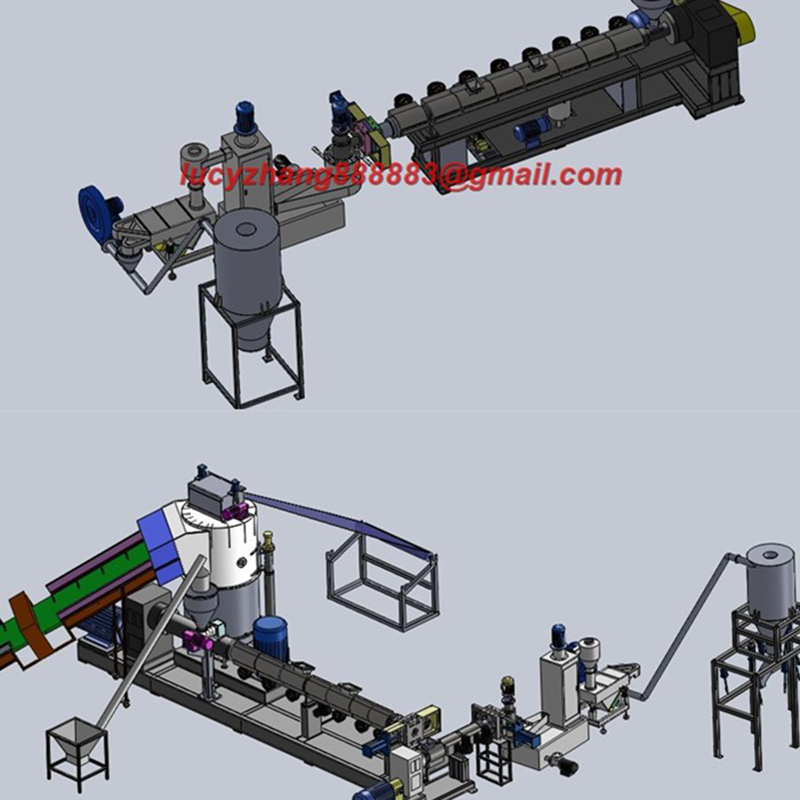

knife production line

Plastic thin wall food container injection molding machine

We are manufacturing different types of injection molding machines and range starts from 50 Ton to 3300 Ton.

We sell injection machines of different tones, different sizes, different model: hybrid type, hydraulic type, all-electrict type injection molding machines.

Product details:

Injection molding machine – high speed injection molding machine

for thin walll plastic product

such as food container. milk tea bottles, juice bottles. cotton bottle,cable ties….

If you want to buy good quality injection machines at competitive price, please send your demands and inquiry to us!

Plastic thin wall food container injection molding machine

CS series high speed thin wall package injection molding machine

More stable and repliable, more rigid mould clamping

The German imported control system makes the machine run more smoothly. With the requirements of the thin-wall packaging mold, the rigidity of the mould clamping mechanism is further strengthened. Mold clamping system is more stale. Faster response, higher injection speed, More energy saving with servo motor system.

Mold clamping system is more stable

Proportional open mode control, faster opening speed, more accurate position control

Faster response, higher injection speed

The new injection unit structure, response speed is increased by 40%, the max injection speed exceeds above 400mm/s

More energy savin servo system

Optimization of servo system, more energy saving and stronger power

Product name:disposable lunch box/container thin wall

Thickness:0.45mm

Cavity:2cavity/4cavity/8cavity

Output:5,000,000-15,000,000 pipeces/year

|

QINGDAO CUISHI PLASTIC MACHINE CO.,LTD |

|||||||

|

TYPE |

FOB QINGDAO USD |

INECTION CAPACITY (cm³) |

OPENING STROKE (mm) |

SPACE BETWEEN TIE BAR(mm) |

|||

|

USD |

MOULD |

USD |

MAKING |

||||

|

CS308 |

36999 |

5KG BUCKET |

10000 |

60 DAYS |

648-878 |

600 |

680*630 |

|

CS358 |

42999 |

10KG BUCKET |

15000 |

60 DAYS |

814-1108 |

660 |

730*680 |

|

CS408 |

52999 |

17KG BUCKET |

30000 |

60 DAYS |

1335-1743 |

720 |

780*730 |

|

CS418 |

68000 |

1568-2024 |

710 |

760*730 |

|||

|

CS488 |

70000 |

1722-2212 |

780 |

830*780 |

|||

|

CS568 |

72000 |

2185-2766 |

835 |

880*830 |

|||

|

CS618 |

98000 |

2665-3330 |

910 |

910*910 |

|||

|

CS658 |

11000 |

2637-3650 |

930 |

960*880 |

|||

|

CS788 |

119888 |

3052-4559 |

1030 |

1060*980 |

|||

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Best quality Double Screw Extruder - thin wall bowls injection machine – Cuishi , The product will supply to all over the world, such as: Peru, Morocco, Accra, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.