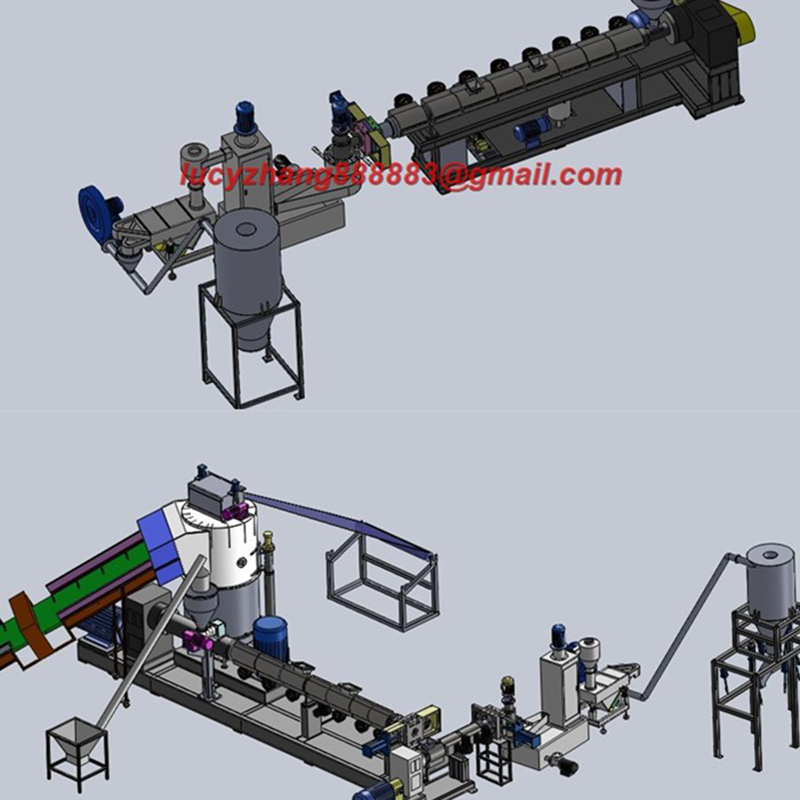

China wholesale PP Hollow Grid Board Extrusion Line - Corrugated Pipe Production Line – Cuishi

China wholesale PP Hollow Grid Board Extrusion Line - Corrugated Pipe Production Line – Cuishi Detail:

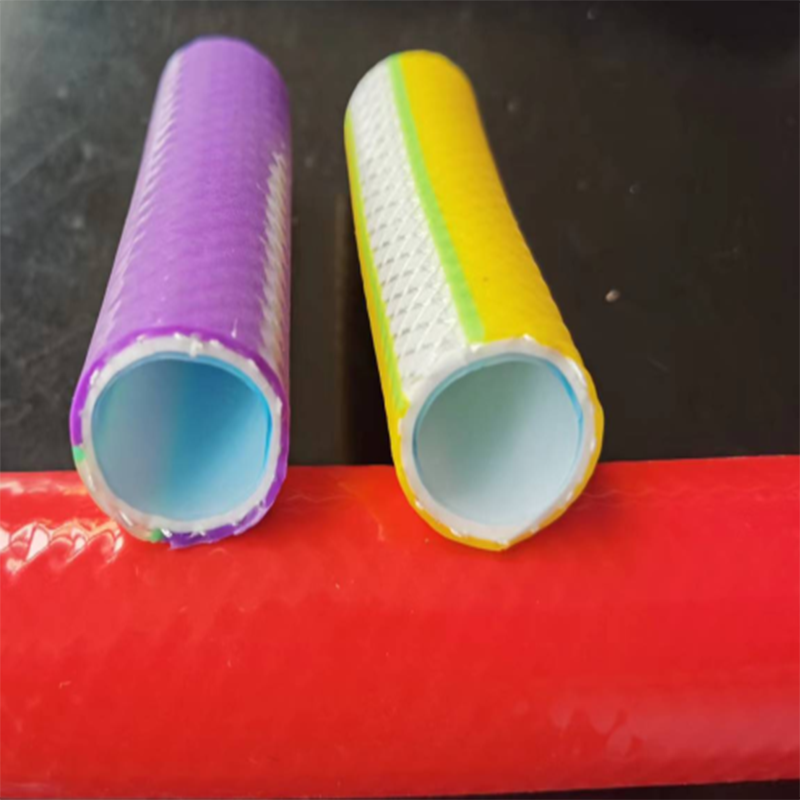

plastic single wall corrugated pipe machine

1. plastic single wall corrugated pipe machine can produce PP PE PA PVC EAV corrugated pipe which is widely used as wire harness protective pipe for car and machine tool

2. equip with vacuum pump, the machine can produce washing machine pipe, air conditioner pipe, hookah pipe, wash basin drain pipe,medical pipe

3.mold transmission by gear

4. water cooling, wind cooling

5. car threading pipe / smocking pipe /shisha pipe/ air conditioner pipe/ washing machine pipe/drainage pipe

Equipment List

|

NO. |

Description |

QTY |

Unit |

remarks |

|

1 |

SJ-75/30 Single Screw Extruder |

1 |

set |

30kw motor |

|

2 |

Die Head Mold |

1 |

set |

chrome inside |

|

3 |

core bar and mouth mold |

1 |

set |

for each size nose |

|

4 |

Forming Mould (60pairs) |

1 |

set |

40cr, Nitriding |

|

5 |

Pipe Forming Machine |

1 |

set |

air&water cooling |

|

6 |

Pipe cutter machine |

1 |

set |

Round Flat HDPE/PVC Plastic Bridge Prestressed Post Tensioning Corrugated Pipe machine extrusion line for Concrete

HDPE Carbon corrugated Pipe Production Line Project

(Pipe dia OD32-Φ200 200mm)

1.1 variable frequency motor 30KW 1 set

1.2 motor drive (Huichuan) 30KW 1 set

1.3 specific requirements:

Due to the adoption of newly designed and optimized screw and sleeve, the extruder has the following advantages: high plasticization rate, uniform melt and continuous and stable production. High performance gearbox reducer. High torque, long service life and low noise.

1) Model SJ-75/30

2) Screw (Zhoushan)

- diameter 75mm – length diameter ratio 30:1

- material 38CrMoAlA – surface treatment Nitriding, polishing

- speed 1-75r/min

3) Barrel (Zhoushan)- material 38CrMoAlA

- internal surface treatment Nitriding, diffractive grinding

- heating method Ceramic heating ring

- heating power 22kw

- cooling system Barrel fan cooling

- cooling power 0.18kw × three

4) Reducer (Guomao)

- box material HT200 - gear form Helical gear

- gear material 20CrMnTi

- gear surface heat treatment and tooth surface quenching

- cooling mode Internal circulating water cooling

5) Drive motor (Qufu Jinsheng)

- mode Variable frequency motor – power 30KW

- variable frequency controller Drive (Huichuan)

6) Control appliance – contactor Siemens

- temperature control instrument Delta

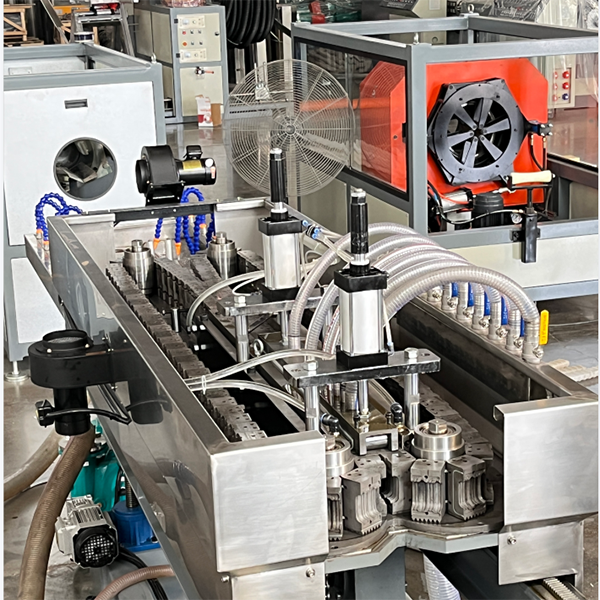

The type diameter is 50-160mm, the material is 40Cr tube embryo die, equipped with stainless steel heater, which has the advantages of fast and uniform extrusion speed, low head pressure and so on.

- extrusion die specification: 55mm*22 with wall thickness 2.5mm , with moulds block 70 pairs

high speed mold for corrugated pipe machine

material: 40 cr with nitrating

mold quantity: 70 pairs

cavity: double size on same mold

5m/min Forming machine and mold for 55mm with wall thickness 2.5mm

The production speed can adjust with wall thickness and shape

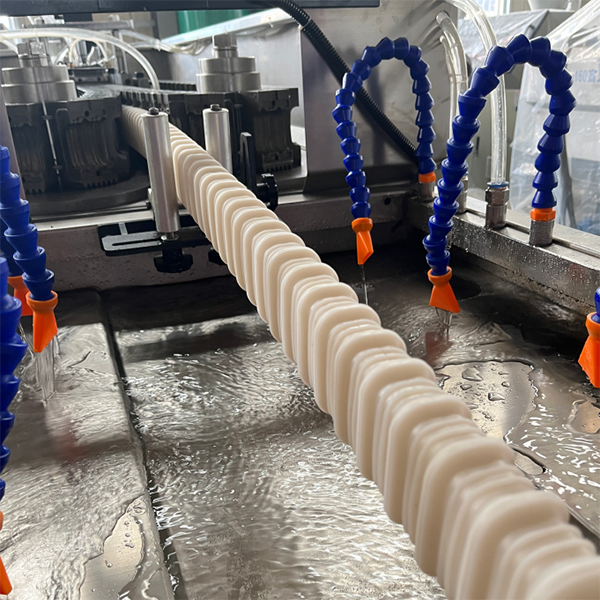

Sbg-160 high efficiency bellows forming machine

- motor power: 4kw (Guomao)

- frequency converter: 3.7KW (Huichuan frequency converter)

- vacuum pump power: 7.5kw

- transmission mode: rack type.

- forward and backward movement: 500 mm.

- up and down movement: 150 mm.

- Fan Power: 180W (2 sets)

- cooling mode of forming machine: water cooling / air cooling

–Oil pump: 1

Qg-160 non cutting machine

- mode Non chipping cutting

- maximum cutting range Ф 50- Ф160

Product detail pictures:

Related Product Guide:

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for China wholesale PP Hollow Grid Board Extrusion Line - Corrugated Pipe Production Line – Cuishi , The product will supply to all over the world, such as: Germany, Malta, Palestine, Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.