Chinese Professional Hdpe Pipe Extruder - large diameter pe hollow wall winding pipe machine – Cuishi

Chinese Professional Hdpe Pipe Extruder - large diameter pe hollow wall winding pipe machine – Cuishi Detail:

(600,700,800,900,1000,1200,1400,1500,1600MM)

LARGE DIAMETER HOLLOW WALL SPRIAL PIPE LINE

D. EQUIPMENT

|

1set

1set 1set 1set 2sets 1set 1set 1set 1set 1set |

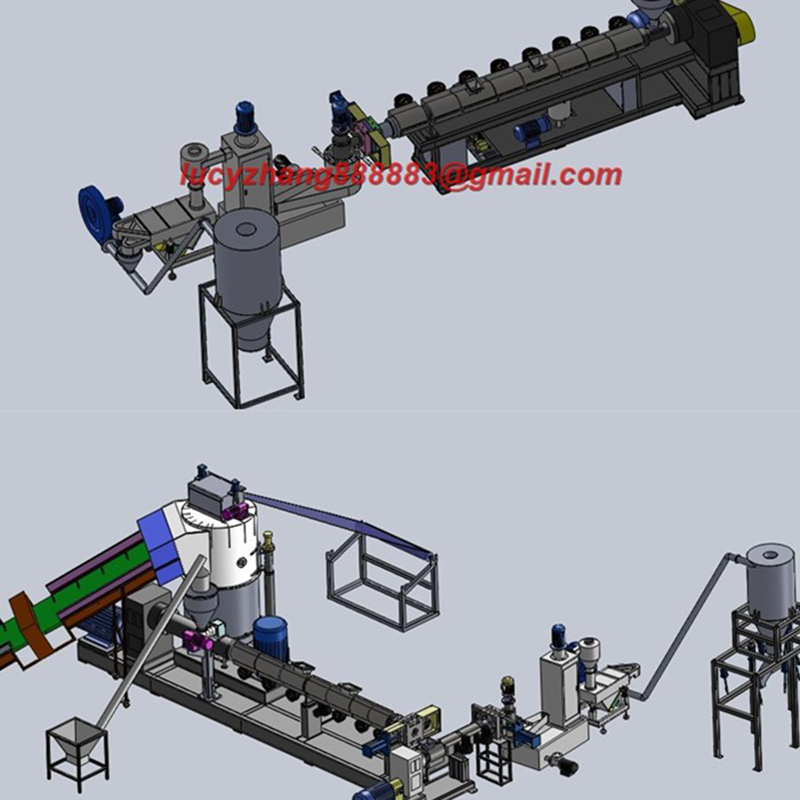

The extrusion line is mainly for producing large diameter hollow wall winding pipe. HDPE hollowness winding pipe has small masses and a low roughness coefficient, are widely used for sewerage systems, storm drains, treatment facilities and sanitation of the old pipeline, well and various sewage tanks are manufactured. Pipes with diameters from 200mm-3500mm and the stiffness classes SN 2,4,6,8,10,12,14,16. Pipe extrusion line first produces square pipes from HDPE, then with the help of a co-extruder and spiral molding machine, spirally wound onto the walls and subsequently welded together forming the pipe body. Pipe extrusion and winding system are separately controlled, can be used separately. The line energy saving, easy to transport and installation, the investment is lower, easy to maintain.

PE winding pipe making machine

The extrusion line is designed with advantaged technology and several patented technologies of our company have been applied.High speed and excellent extrusion quality by adopting two sets of single screw extruder with high efficiency performance. Unique design of composite die-head for large diameter winding pipe processing with high production efficiency. High quality of winding pipe produced by adopting the unique winding process. Easy operation and high performance by adopting an advanced PLC control system with touch LCD.

|

Mode |

CS-800 |

CS-1200 |

CS-1600 |

CS-2400 |

CS-3600 |

|

Output(kg/h) |

350 |

500 |

700 |

1100 |

1400 |

|

Pipe diameter(mm) |

200-800 |

400-1200 |

800-1600 |

1200-2400 |

2000-3600 |

|

Production speed(m/h) |

2-16 |

2-14 |

1-10 |

0.5-8 |

0.3-6 |

|

Installed power(kw) |

180 |

250 |

300 |

400 |

500 |

E. TECHNICAL PARAMETER OF EQUIPMENT

| Ⅰ.Hollow square stock extruder model:SJ100X301.1 type1.2 Center height1.3 Max output2. screw

1. diameter 2. L/D 3. material 4. surface treatment 5. depth of nitration 6. rotate speed 3. machine barrel 3.1. material 3.2. surface treatment 3.3. depth of nitration 3.4. heating zone 3.5. heating type 3.6. heating power 3.7. cooling type 3.8. cooling power 4. positive gear box 4.1 material of box 4.2 gear type 4.3 gear material 4.4 axle 4.5 material of axle 4.6 lubrication system 5. main electric machine 5.1 type of electric machine 5.2 power of electric machine 5.3 rotate speed 5.4 timing 5.5 power 6. loading equipment 6.1 type 6.2 power 6.3 max convey ability |

Single screw extruder1000mm600kg/h100mm

30 38CrMoAlA nitrogen 0.50-0.70mm 0-140r/min

38CrMoAlA nitrogen 0.50-0.70mm 6 Ceramic heating collar 56kw Blower cooling 0.25kwX6

HT200 Bevel wheel 20CrMnTi, carburation,quenching imported 40Cr Pressure lubrication

AC motor 90kw 1500 r/min 1set (ABB) 3p*380V*50HZ

Vacuum loading automatically 2.2kw 1000kg/h |

:

Ⅺ. provide free spare parts with machine( 2 years consumption)

|

model |

Spare parts |

amount |

remarks |

|

SJ100X30 SJ75X30 |

Machine barrel thermoelectric pair |

6 pcs |

|

|

Power off protection |

6 pcs |

||

|

AC contactor |

6 pcs |

||

|

Middle contactor |

6pcs |

||

|

button |

6pcs |

||

|

Option switch |

6pcs |

||

|

Stain steel heating collar |

3set |

||

|

controller |

3pcs |

RKC、FUJI |

|

|

O type ring |

3set |

||

|

Gear axle oiltight |

6 pcs |

||

|

Temperature controller |

6 pcs |

||

|

Electric carbon brush |

3sets |

||

|

Cross screw driver |

2pcs |

||

|

Straight screw driver |

2pcs |

||

|

General utility wrench |

2pcs |

||

|

Inner hexagon spanner |

2sets |

Selected by mold |

|

|

vacuum(spray)sizing water tank 100 |

nilometer |

12pcs |

|

|

slirubber |

6㎡ |

||

|

Sealing spare parts |

50~60m |

||

|

Single nuzzle |

100pcs |

||

|

Power off protection |

8pcs |

||

|

AC contactor |

8pcs |

||

|

Middle contactor |

8pcs |

||

|

Electromagnetic value |

6pcs |

||

|

Forming machine 2000 |

Roller axle |

20 pcs |

|

|

axle |

30 pcs |

||

|

Cutting device 105 |

Saw bit |

6pcs |

|

|

Electromagnetic value |

6pcs |

||

|

Electromagnetic switch |

3 pcs |

||

|

Air tube |

50m |

||

|

Soft tube |

15m |

||

|

throat bone |

10pcs |

||

|

Square pipe die head |

Thermoelectric pair |

3pcs |

|

|

Stain steel heating collar |

2set |

||

|

High strength screw |

30pcs |

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for Chinese Professional Hdpe Pipe Extruder - large diameter pe hollow wall winding pipe machine – Cuishi , The product will supply to all over the world, such as: Italy, Zurich, Bulgaria, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!