Chinese Professional Plastic Crushing Machine - 100-3000kg/h Vertical PVC Hot And Cold Mixing Machine – Cuishi

Chinese Professional Plastic Crushing Machine - 100-3000kg/h Vertical PVC Hot And Cold Mixing Machine – Cuishi Detail:

100-3000kg/h Vertical PVC Hot And Cold Mixing Machine

Plastic Mixer For Sale

Applications:

1.Blending Master Batch with the virgin granules.

2.Mixing Pigments or Pigment Paste with granules or polymers powder.

3.Blending Pigment and Fillers additives.

Description:

The unit combines heat mixing and cool mixing together.The materials after heat mixing can be gotting into cool mixer for cooling automatically,exhausts remaining gass and avoids agglomerates.

It is an ideal equipment for plastics mixing.

Features:

1) All important parts(bowl, mixing tool, control cabinet) are manufactured in our factory, which ensure the quality of machine.

2) All material in contact with product is in SS304 or aluminum alloy and the product will nor be contaminated.

3) High cooling efficiency, short mixing time, easy and convenient to clean, and can reach high output.

PLASTIC MIXER

Specification of plastic mixer

SRL-Z200/500 hot and cooling mixer units

1. Application: Mix raw material

2. Output: ≤350kg/hour

3. Equipment components:

① hot mixer ② cooling mixer ③ autoloader

4. Features:

Mechanical parts:

Pot body adopt SUS304 stainless steel which has very good smooth and rigid surface with features of wearable, corrosion resisting,heat resisting, no-stick with raw material

Hot mixer cover material adopt ZL102 casting aluminum with polished surface

Hot and cooling mixer open adopt cylinder pneumatic drive; the main shaft of hot and cold mixer adopt NSK brand which has features of reliable stable working performance.

Hot and cooling sealing adopt silicon rubber sealing with reliable sealing effect and not deformation even at high temperature.

Stirring paddle past dynamic balance testing which lower noise and improve lifespan

Electric parts: Adopt intelligent RKC thermo control; Adopt famous brand motor

1. SRL-500/1000 hot and cooling mixer units

Technical parameters and related performance of equipment:

1. hot mixing part

Total volume of hot mix 510L

Effective volume of hot mix 380L

Feeding quantity per time 180-230kg/ pot

Productive capacity 720-920kg/h

Motor power 75kW (Kejie motor)

Slurry type Linear three-layer mixed slurry (stainless steel)

Bottom thickness 5mm

Thickness of inner wall of boiler 5mm

Hot mix speed 748 rpm

Mixing time 8-10 min / pot

Temperature during mixing operation ≤150℃

2. cold mixing

Volume of cold mixer 1000L

Effective volume of cold mixing 800L

Motor power 11KW

Reducer model WPO175 1:20

Cold mixed slurry One set of slurry stainless steel

Thickness of inner wall of boiler 5mm stainless steel

Thickness of outer wall of boiler 5mm iron pot

Bottom of pot 5mm stainless steel 8mm iron

Mixing speed 49 rpm

Cooling time 10-15 min / pot

Water supply in the interlayer of the cold mixing boiler Water pressure ≤ 0.3MPa

Water consumption 12 tons / hour (can enter the pool for recycling)

Most suitable discharging temperature ≤45℃

Suitable for water temperature 10-18℃

3. electrical part

Universal frequency converter 75kW, Tianzheng Zhengtai Electric Appliance, with heat dissipation and exhaust holes in the electric box

4. unloading method And lid

All pneumatic discharging and pneumatic cover lifting.

- the feeding machine adopts screw feeding machine

SRL-W800/2500mixer group

A. Necessary Machines for PVC compounding plant

1 set of SRL-Z800/2500 mixer

1 set of vacuum loader

B.1. Detail Technical Parameters of SRL-Z 800/2500liter

| 1 | Model | / | SRL-Z800/2500 mixer group | |||

| Hot mixer | ||||||

| 1 | total volume of hot mixer | L | 800 | |||

| 2 | effective volume of hot mixer | L | 600 | |||

| 3 | material weight/batch | ㎏/batch | ≤260 | |||

| 4 | Output | ㎏/h | ≤1300 | |||

| 5 | motor power | KW | ABB inverter 110KW , | |||

| 6 | Thickness of wall of barrel(stainless steel 304 ) | mm | 12 | |||

| 7 | Thickness of bottom of barrel (stainless steel 304 ) | mm | 16 | |||

| 8 | hot mixer rotating speed | r/min | 370/740rpm | |||

| 9 | Quantity of stirring blade | pcs | 3(1Cr18Ni9Ti) | |||

| 10 | mixing time | min/batch | 7-10 | |||

| cooling mixer | ||||||

| 1 | cooling mixer volume | L | 2500 | |||

| 2 | effective volume of cooling mixer | L | 1870 | |||

| 3 | motor power | KW | 30 | |||

| 4 | material of cooling mixer blade | / | ZG1Cr18Ni9Ti | |||

| 5 | stirring blade rotating speed | r/m | 50 | |||

| 6 | Thickness of wall of barrel(stainless steel 304 ) | mm | 10 | |||

| 7 | Thickness of bottom of barrel(stainless steel 304 ) | mm | 14 | |||

| 8 | lift control method | / | pneumatic | |||

| 9 | Cooling method | / | water cooling | |||

| 10 | cooling time | min/batch | 10 | |||

| 11 | Total weigth of the overall machine | kg | 8800 | |||

| 12 | Whole size of the control panel | mm | 800mm×500mm×1800mm | |||

| 13 | Whole size of the machine | mm | 5750mm×3250mm×4500mm | |||

Detail Technical Parameters of Spiral feeder

| Item | Description | Unit | remarks | |

|

1 |

Transport tube diameter | mm | 141 | |

|

2 |

Charging motor power | KW | 3.8 | |

|

2 |

Push material motor power | KW | 0.55 | |

|

4 |

Charge capacity | Kg/h | 800-1500 | |

|

5 |

Storage volume | kg | 300 | |

|

6 |

Material of storage hopper and tube | / | Stainless steel | |

|

7 |

This machine will load the raw material to the mixer ‘s hopper automatic, it will increase work efficency | |||

SRL-W1000/3500mixer group

| 1 | a、hot mixer |

| Model SRL-W1000/3500Hot mixer total volume 1000LHot mixer effective volume 750L

material weight/batch 280-350㎏/batch Capacity 1500-1900㎏/h Motor power 160kw Normal we sell with 132kW , now 160KW for you ! Speed adjusting mode frequency conversion Inverter brand holip Blade type straight-line-style and four layer mixer blade inside wall thickness 8mm(1Cr18Ni9Ti) Normally we do is 6MM , we give you 8 MM barrel bottom thickness 12mm(1Cr18Ni9Ti) Normally we do is 8MM , we give you 12MM Hot mixer rotating speed 300/600 r/m Mixing time 8-12min/batch Material 304# stainless steel Treatment of mixer wall polished Heating method sell-friction Cover opening method: pneumatic working temperature ≤150℃ |

|

| 2 | B. cooling mixer |

| Structure horizontal methodvolume 3500Lcooling mixer effective volume 2275L

motor power 37Kw Normal we use the motor is 22kw , 30KW , we match for you 37K cooling mixer blade substance ZG1Cr18Ni9Ti barrel wall thickness 8mm stirring blade rotating speed 75r/m cooling time 6-8min/batch interlayer in cooling mixer conducts water water pressure≤0.3Mpa water consumption: 10-15T/hr (can be recycled) cooling water temperature ≤45℃ appropriate temperature 14-19℃ opening method : pneumatic diameter of discharging mouth Φ350mm Discharging mouth height above ground 350mm

|

|

| 3 | C、electric parts |

| Motor for hot mixer: 160kw(frequency conversion)Inverter is Holip brandelectric components adopt SIEMENS

Temperature controller adopts RKC from Japan. Control panel is attached with a de-heat fan. Control panel overall size: 800×500×1800mm。 Equipment overall size 4750×3250×4500 Equipment overall weight 8800Kg |

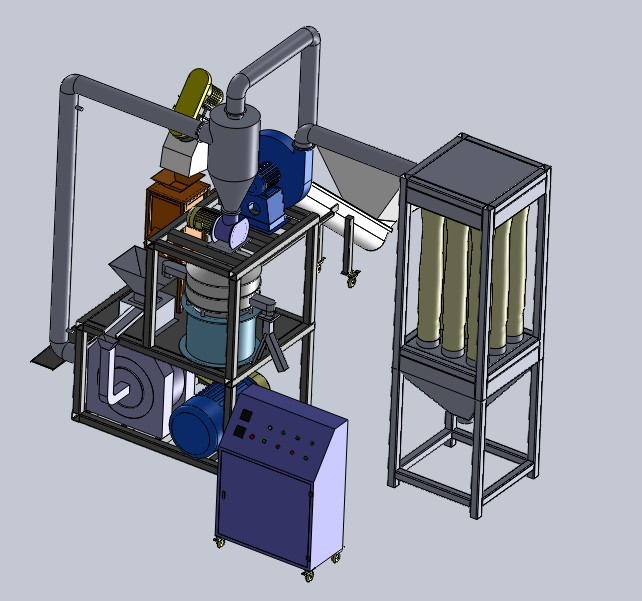

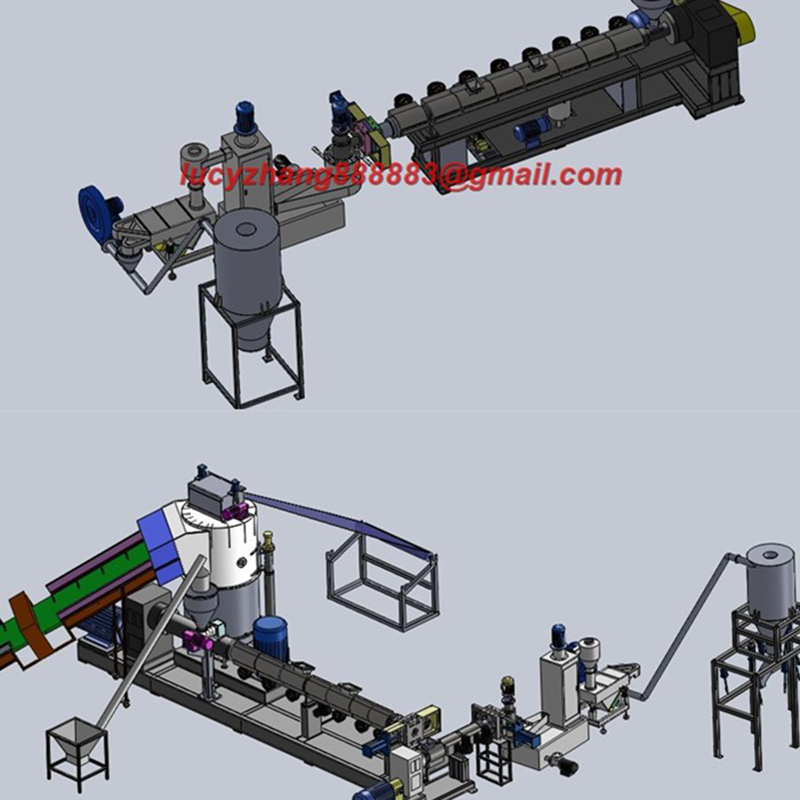

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Chinese Professional Plastic Crushing Machine - 100-3000kg/h Vertical PVC Hot And Cold Mixing Machine – Cuishi , The product will supply to all over the world, such as: Mauritius, Poland, Muscat, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.