Chinese wholesale Board Extrusion Line – PVC Foam Board Extrusion Machine – Cuishi

Chinese wholesale Board Extrusion Line – PVC Foam Board Extrusion Machine – Cuishi Detail:

Product Description

Main feature of Plastic PVC WPC wood plastic composite foam board extrusion line/door board Making Machine/extruder:

- Frequency converter:SIEMENS;

- 2.Full set Siemens electric parts: Main motor/AC contactor/thermal overload relay/circuit breaker(including the large circuit breaker of the whole line)/comment switch;

- 3.PLC:SIEMENS

- 4.Temperature controller:OMRON Japan

- 5.Relay/travel switch:Schneider France

- 6.Twin-Screw: famous brand from Zhoushan,China

- 7.Mould:China famous brand like:JC Times/EkO/Weilei

|

WPC PVC Celuka foam board basic information: |

|

|

Main material |

PVC/CaCo3/addtives |

|

Finished board size |

1220-2050mm(width)*2440mm(length-adjustbable) |

|

Finished board thickness range |

3-25mm/3-30mm/3-40mm |

|

Max extruder capacity |

400kgs/h/600kgs/h/800kgs/h/1000kgs/h |

|

Board surface treatment |

Embossing/transfer print/lamination/uv coating/CNC engrave |

|

Extruder Mold |

|

SYSJ-80/156 |

SYSJ-80/173 |

SYSJ-92/188 |

|

Output capacity |

kgs/h |

350 |

550 |

650 |

|

Output thickness |

mm |

3-25 |

3-30 |

3-30 |

|

Machine List |

|||

|

No. |

Name |

Qty. |

Remark |

|

1 |

Screw loader for extruder |

1 |

|

|

2 |

SJZ 80/156 conical twin screw extruder |

1 |

|

|

3 |

Extrusion mould unit |

1 |

1220*2440 |

|

4 |

Vacuum calibration Table |

1 |

|

|

5 |

Cooling bracket |

1 |

|

|

6 |

Haul off unit |

1 |

|

|

7 |

Edge cutting device |

1 |

|

|

8 |

Tracking cutter |

1 |

|

|

9 |

Automatic shift machine |

1 |

|

|

10 |

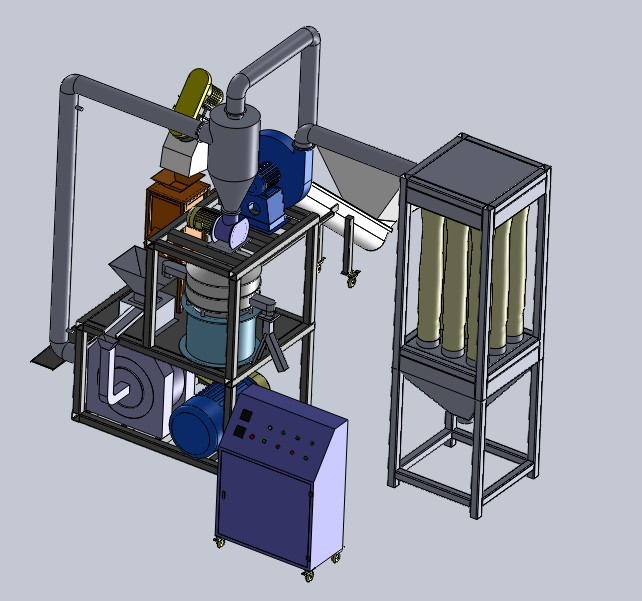

Dust collection device |

1 |

|

|

11 |

Mould temperature controller |

1 |

|

|

Auxiliary Machine |

|||

|

12 |

SRL-Z Series Mixer unit |

1 |

Capacity : 450-550kg/h |

|

13 |

Screw loader for Mixer |

1 |

|

|

14 |

Crusher |

1 |

Power: 11kw,22kw,30kw |

|

15 |

Pulverizer |

1 |

Power: 45kw,55kw,75kw |

List of machines and advantages

Production line&Auxiliary machines:

|

Part a: Plastic WPC PVC wood plastic composite foam board extrusion line/door board making machine |

||||

|

NO. |

Machine name |

Type |

Qty. |

Note |

|

1 |

Conical twin screw extruder |

SJSZ80/156 SJSZ92/188 |

1set |

with spring up loader |

|

2 |

Electric control system |

1set |

Siemens electrical parts |

|

|

3 |

T-mould |

1set |

JC Times/Eko/Weilei |

|

|

4 |

Calibration unit |

1set |

size:1500*600*100mm |

|

|

5 |

Cooling bracket |

1set |

5000mm(length)*1500mm(width) |

|

|

6 |

Haul-off device |

1set |

8pairs/10pairs/12pairs |

|

|

7 |

Shearing unit in length and width |

1set |

||

|

8 |

Dust vacuuming collector |

1set |

||

|

9 |

Stacker |

1set |

2500mm*1750mm |

|

|

NO. |

Name of machine |

Advantage of machine |

|

1 |

Automatic feed loader |

Fully automatic |

|

2 |

Conical Twin Screw extruder |

Inovince servo motor, famous brand gearbox and full set of SIEMENS electric control system,30% ENERGY SAVING, STABLE RUNNING, LONG SERVICE LIFE

|

|

3 |

T-die |

Design by ourself with over 23 years manufacturing experience Extrusion and calibration mould Technical parameters: a.Unique die structure for hollow products using core molding optimized flow path through computer simulation to ensure uniform and stable flow. b.Independent air flow control system to quickly balance the airflow in a short time to obtain a stable production . c.Fine polishing of the cavity , lip and flowing channel. |

|

4 |

Calibrator |

100mm thickness mirror surface calibrator |

|

5 |

Cooling Bracket |

9 pcs stainless iron rollers |

|

6 |

Haul off machine |

8-12 pairs rubber surface rollers |

|

7 |

Transverse cutter |

Technical parameters: a.Special positioning to ensure cutting accurecy. b.Special knife structure, safe and stable c.PLC control system, double dust system.

|

|

8 |

Stacker with automatic robert board lift |

|

|

Auxiliary machines(optional) |

||

|

1 |

Crusher |

For recycling unqualified board |

|

2 |

Grinder |

For recycling unqualified board |

|

3 |

High-speed Heat/Cooling Mixer |

For mixing raw materials |

|

4 |

Chiller |

To supply cool water |

Number of setting plates: 4 pairs

Setting plate width: 600mm

Thickness of setting plate: 90mm

Length of setting plate: 1500mm

Treatment process: quenching and tempering + hard chromium plating + polishing

Cooling of setting plate: water cooling, specially designed flow channel, good cooling effect

Lifting of setting plate: hydraulic control, separate lifting control

Adjustment mode of upper formwork: fine adjustment screw

Treatment process of lifting guide post adjusting column: quenching and tempering + hard chromium plating + polishing

Front and rear walking mode of electric platform

Electric power: 0.37kw

Reducer form nmrv-40 / 75-500-0.37

Overall height adjustment mode of platform: manual adjustment

Platform overall control independent control panel

The control panel is composed of power indicator, main engine on-off switch, emergency stop button, tachometer, fine adjustment button, v

|

Pvc Foam Board Physical Properties |

||

|

Testing Item |

Unit |

Testing Result |

|

Density |

g/cm3 |

0.35-1.0 |

|

Tensile Strength |

Mpa |

12-20 |

|

Bending Intensity |

Mpa |

12-18 |

|

Bending elasticity Modulus |

Mpa |

800-900 |

|

Impcting Intensity |

KJ/m2 |

8-15 |

|

Breakage Elongation |

% |

15-20 |

|

Shore hardness D. |

D |

45-50 |

|

Water Absorption |

% |

≤1.5 |

|

Vicar Softening Point |

ºC |

73-76 |

|

Fire Resistance |

|

Self-Extinguishing Less than 5 seconds |

Product detail pictures:

Related Product Guide:

Our commission is to serve our users and clients with best quality and competitive portable digital products for Chinese wholesale Board Extrusion Line – PVC Foam Board Extrusion Machine – Cuishi , The product will supply to all over the world, such as: Brasilia, Japan, moldova, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!