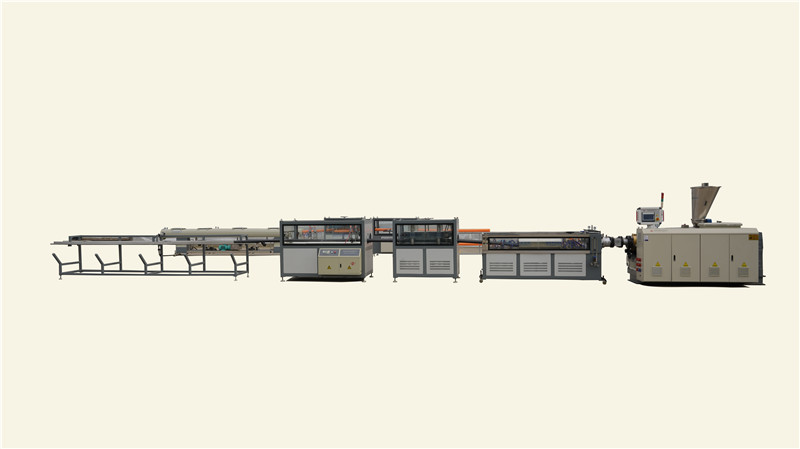

Chinese wholesale Board Extrusion Line – SJSZ-80/156 pvc foam board extrusion machine – Cuishi

Chinese wholesale Board Extrusion Line – SJSZ-80/156 pvc foam board extrusion machine – Cuishi Detail:

| Name of Commodity380V .3P.50HZ

|

Quantity |

|

PVC WPC FOAM BOARD PRODUCTION LINE From extruder to stacker 1.automatic feeding system 2.SJSZ80/156 conical twin screw extruder 3. T -die mould ( L2450, W1220,T:3-25mm) 4.cooling calibration platform -4 couples calibrators 5.Mould temperature controller 2 sets 6.cooling support 7.eight pairs rubber rollers traction with Trimming and dust collector 8.cutting machine 9.Automatic discharge and stacker/robert |

1 |

|

20HP chiller |

1 |

|

0.8MPA air compressor |

1 |

|

SWP360 crusher |

1 |

|

SMF630 pulvertizer machine with vibrating system |

1 |

|

SHR500/1000 heating/cooling mixer |

1 |

| No | Name | Type | Quantity | Marks |

| 1.1 | Conical twin screw extruder

With automatic screw feeder |

SJSZ-80/156 | 1set | Equipped with automatic screw feeder |

| 1.2 | Electrical control system | 1set | Delta frequency converter, Siemens contactor | |

| 1.3 | Mould | SJM-1350 | 1set | Oil string device at die port, automatic temperature control |

| 1.4 | Vacuum setting die | SDX-1500 | 1set | 4-stage sizing cooling |

| 1.5 | Hauling off | SQY-1400 | 1set | 8 sets, 16 rolls. |

| 1.6 | Cooling bracket | SJTJ-3000 | 1set | |

| 1.8 | cutting machine | SQG-1220 | 1set | |

| 1.9 | Plate unloading device | SJS-1220 | 1set | |

| 1.10 | Hot and cold mixer | SHR500/1000 | 1set | |

| 1.11 | Crusher | SWP-380 | 1set | |

| 1.12 | Grinder | SMP-630 | 1set | |

2.instruction

| NO | INSTRUCTION | SPECIFICATION |

| 2.1 | RAW MATERIAL | PVC Add auxiliary materials |

| 2.2 | BOARD SIZE | 3-25×1220 |

| 2.3 | Line speed | 0.2-0.8m/min |

| 2.4 | MAX OUTPUT | 350-450kg/h |

| 2.5 | MACHINE SIZE | 26000×2200×2900 L×W×H |

| 2.6 | WEIGHT | 35t |

| 2.7 | Total installed power | 185kw |

| 2.8 | Actual energy consumption power | 125kw |

| 2.9 | Gas consumption | 0.4m3/min |

| 2.10 | pressure | 0.6mpa |

| 2.11 | Water circulation | 0.4 m3/min |

| 2.12 | VOLTAGE | AC380V±10%50HZ |

| 2.13 | WATER | Industrial water, free of impurities, filtered, water pressure: 0.4MPa, water temperature: 15-25 ℃. |

| 2.14 | work environment | 0-40℃ |

| 3.technological process |

| Raw material allocation→LOADER MATERIAL → EXTRUDER→T DIE MOULD→CALIBRATION TABLE→COOLING FRAME →8 ROLLERS HAULING OFF→ Longitudinal cutting device→Transverse cutting →transportation→test →package |

| 4、1conical twin screw extruder |

|

| 4.2Electrical control system |

| Frequency converter: ABB /holip /Delta/innovince frequency converterContactor: Siemens contactorThe control panel consists of power indicator, main engine on-off switch and emergency stop button.

Low voltage electrical appliances are Siemens or Schneider products, and the main air switch is Delixi products |

4.5 hauling off

| Rubber roller material: nitrile rubberTraction cots: 8 groups of 16 Cots

Rubber roller hardness: Shore hardness 53-58 degrees Control mode: pneumatic compression, independent control Working width of rubber roller: 1400mm Move back and forth synchronously with the platform The connection mode with the platform is the mother screw and can be adjusted separately |

4.7 cutting machine

Cutting mode: Electric transverse cutting

Thickness of cut plate: 3-25mm

Cutting plate width: 1220 mm

Dust suction device is common to slitting

4.8 board robert /automatic board lifting machine

main parameter configuration of special plate splicer for plate

1、 Overall dimension of equipment: 6500 * 1890 * 2600 (5000) mm;The height of the saw is 1150mm-980 mm, which can be adjusted with the center of the saw, and can be connected with the cutting table by the bracket;

2、 Electrical system:

- Operation mode: PLC + touch screen, brand: Xinjie

2. Low voltage apparatus: Omron, Siemens, Schneider;

3. Alignment mode of plate conveying: stainless steel idler, idler Φ 60mm, number of idler 18, idler drive is cycloid reducer controlled by frequency converter, reducer model is bwy0-9-0.75kw, frequency converter brand: Xinjie;

4、 Lifting system: variable frequency speed regulating brake motor drive, RV Reducer rubber roller guide vertical lifting, motor power 1.0kw, reducer rv63-25, frequency converter brand: Xinjie;

5、 Translation system: servo motor drive RV Reducer, reducer rv63-10, servo motor model: 80st-0.75kw, brand: Xinjie

6、 Plate grabbing method: vacuum suction cup, number of suction cups: 10;

7、 Maximum stacking height: 1400mm;

8、 Maximum grasping weight: 50kg;

9 Maximum operating speed: 50s / time;

10、 Suitable plate size: 1000-3200mmx1220mm;

PVC foam board machine Spare parts :Accessories list:

| NO | Spare parts name | Quantity |

| 1 | Cast alumium heater for 1 zone | 1 pcs |

| 2 | Cooling air fan for barrel | 1 pcs |

| 3 | Spanner for mould | 1 pcs |

| 4 | contactors | 2 pcs |

| 5 | Thermocouples | 5 pcs |

| 6 | heating rods for abrasives | 5 pcs |

| 7 | copper feeler gauge | 1pcs |

| 8 | die adjusting bolts | 5 pcs |

| 9 | Feeding spring for feeding machine | 2 pcs |

| 10 | Pe pipe for feeding machine | 2 pcs |

| 11 | air pipe connectors | 5 pcs |

4.9 SWP380 crusher

| Moving knife 3 piecesFixed knife 2 pieces

Sieve diameter Φ 10mm Large inlet 480 × 320mm Crushing particle size 3-10mm Output 500kg / h Equipped with power of 15kw Wind power 2.2kw Overall weight 2500kg Overall dimension 2 × one point two × 2.4m |

SHR500/1000 hot and cold mixer

| High speed mixer: shr500 / 1000

Material and composition of pot body: 1Cr18Ni9Ti stainless steel, with extremely smooth and hard inner surface, which is characterized by wear resistance, corrosion resistance and not easy to stick. Pot cover material: cast aluminum (the frequency converter controls the motor, with small starting current and more than 30% power saving.) Cooling motor: 15 kw Mixing time: 6-10min Material of discharge body: cast aluminum Unloading mode: pneumatic unloading |

20HP chiller Parameters and configuration table of chiller of Qingdao cuishi

| PARAMETER

CONFIGURATION MODEL |

SYF-20 |

|

| Refrigerating capacity |

Kw 50Hz/60Hz |

59.8 |

| 71.8 | ||

| Power supply and electrical components

(Schneider, France) |

380v 50HZ | |

| Refrigerant

(Eastern Mountain) |

Name | R22 |

| The control mode | Internalbalance expansion valve(Hongsen) | |

| The compressor

(Panasonic) |

Type | Closed vortex type(10HP*2 sets) |

| Power(Kw) | 18.12 | |

|

The condenser (Shunyike) |

Type |

High efficiency copper clad aluminum fins +low noise external rotor fan |

| Fan power and quantity | 0.6Kw*2 sets(Juwei) | |

| Cooling air volume(m³/h) | 13600(Model 600) | |

|

The evaporator (Shunyike) |

Type | Water tank coil type |

|

Frozen water volume(m³/h) |

12.94 | |

| 15.53 | ||

| Tank capacity(L) | 350(Stainless steel, external insulation) | |

|

Water pump (Taiwan Yuanli) |

Power(Kw) | 1.5 |

| Lift(m) | 18 | |

| Flow rate(m³) | 21.6 | |

| Pipe diameter interface | DN50 | |

|

Security and protectio |

Compressor overheat protection, overcurrent protection, high and low pressure protection,overtemperature protection, phase sequence/phase protection, exhaust overheat protection. | |

Product detail pictures:

Related Product Guide:

Our improvement depends on the superior equipment, excellent talents and continuously strengthened technology forces for Chinese wholesale Board Extrusion Line – SJSZ-80/156 pvc foam board extrusion machine – Cuishi , The product will supply to all over the world, such as: venezuela, Seychelles, Manchester, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.