Factory wholesale Plastic Millling Machine - High output Plastic Millling Machine for pvc pe – Cuishi

Factory wholesale Plastic Millling Machine - High output Plastic Millling Machine for pvc pe – Cuishi Detail:

Description Of Goods:

|

Name of Commodity |

Quantity

|

UNIT PIECE (USD) |

FOB qingdao (USD)

|

| SMP400 mill PVC ( output 100-200kg/h) | 1 set | 4000 | 4000 |

| SMP500 mill PVC ( output 250-300kg/h) | 1 set | 8000 | 8000 |

| SMP 600 mill PVC ( output 350-400kg/h) | 1 set | 9500 | 9500 |

| SMP 800 mill PVC ( output 450-600kg/h) | 1 set | 12800 | 12800 |

|

FOB qingdao (USD) |

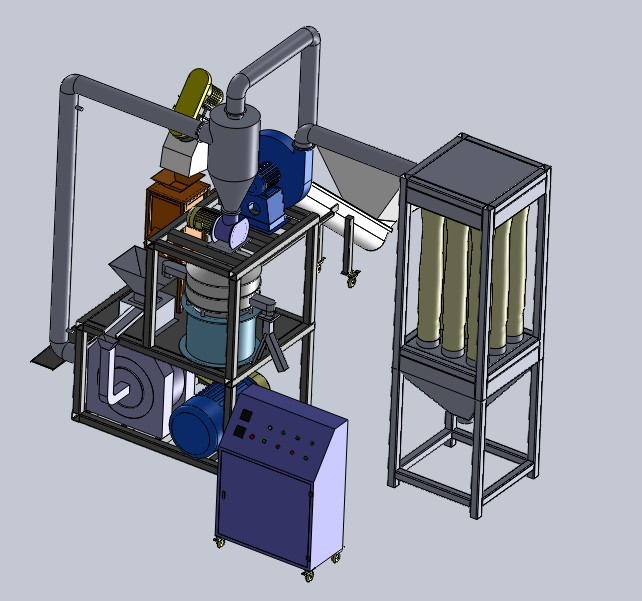

1. Model: SMP-400 WPC PVC miller/pulvertizer

2. crushing chamber diameter: Φ400mm <45 # steel heat treatment processing>

3. Rotor: 3 <45 # steel heat treatment processing>

4. The rotary milling cutter: 60 <45 # steel heat treatment, hardness 58 degrees>

5. Spindle Speed: 3400 ~ 3700r / min

6. Motor power: 30Kw

Note: The machine uses water cooling, make sure not to wear a plastic body in plastics, water 1000Kg / h in use.

Main Features

1. Simple adjustment of cutting gap

2. Fast and easy replacement and adjustment of discs

3. Easy temperature control

4. Low drive power, cost effective operation

5. High throughput

6. Long service life of the disc when sharpened

7. Low residence time means lower thermal stress on the process material

|

NO |

MF-400 |

MF-500 |

MF-600 |

MF-800 |

|

Diameter of disc(mm) |

350 |

510 |

600 |

800 |

|

Main motor power(kw) |

22-30 |

37-45 |

55 |

75 |

|

Cooling method |

Wind Cooling ,Water Cooling |

|||

|

Fan power (kw) |

|

5.5 |

7.5 |

11 |

|

Sieve |

30-40mesh |

|||

|

Capacity(kg/h) |

80 |

120-220 |

200-280 |

250-450 |

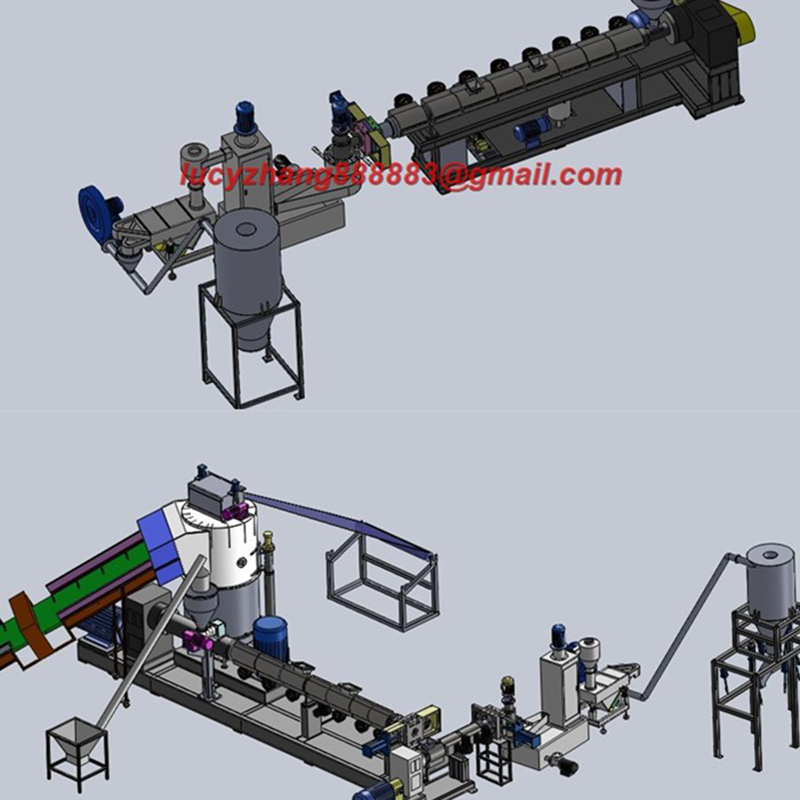

Plastic SMF500 PVC PP PE grinding milling machine / plastic mill pulverizer

PVC PP PE pulverizer can be used for PVC,PP, LDPE, HDPE material. The mesh after pulverizing can be 30-50 mesh.The capacity from 80-450kg/h. The pulverizer machine including: vibration feeder, milling host, vibration sieve, dust collecting system. and special requirement on pulverizer can be customized.

Product detail pictures:

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for Factory wholesale Plastic Millling Machine - High output Plastic Millling Machine for pvc pe – Cuishi , The product will supply to all over the world, such as: Singapore, Turkmenistan, Russia, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our products. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.