Galvanized Steel Strip metal corrugated pipe forming machine

Fully automatic prestressed metal bellows production equipment configuration list

First, the production of technical conditions

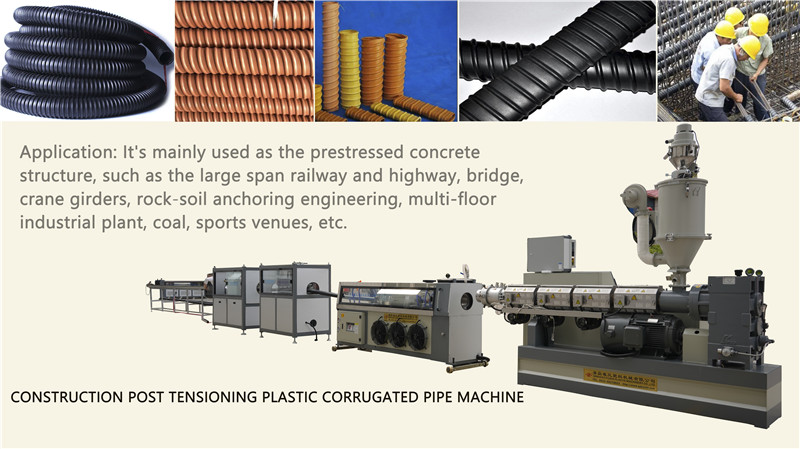

The products produced by this machine comply with the construction industry standard of the People's Republic of China JG/T225-2020

1. Adapt to power supply: 380v/3p/50Hz

2. Adaptable material: galvanized steel strip

3. Extrusion capacity: 1200M/H (max), 8 hours is 8000-10000m

4. Product specifications: prestressed metal bellows

5. Production line speed: 1-21m/min

6. Extruder center height: 1150mm

7. Operation direction: from left to right

8. Installed capacity: 20Kw

9. Equipment size: 2.4M*1.9M*2.4M , weight is 1.7tons

10 steel strip 78mm wide, thickness 0.23-0.6MMM

11. Main Motor : 15 kw + 2.2kw motor and inverter control and gearbox

12. Control system : Siemens brand

Second, the composition of the equipment

1. Siemens Host/metal corrugated pipe forming machine 1

2. Mold diamete 40,45,50, 55, 60, 65, 70, 75, 80, 85, 90, 95

3. FZ-9 flip table 1

4. 1 discharge frame

5. 1 welding machine

1. Gearbox

| gear form | helical gear |

| Gear Material | 20CrMnTi |

| gear surface heat treatment | Tooth surface carburizing and grinding |

2.motor

| Motor control | Inverter motor |

| Motor power | 15KW |

| Motor Controller | Variable frequency speed regulation (sinee) |

| maximum speed | 1470r/min |

| Motor picture |  |

3 Electricity control box

| Contactor | Siemens |

| PLC touch screen | Siemens |

4. Cutter

| 1.cutter motor 1set | |

| Max rotate speed : | 3000r/min |

| Start way : | Limit switch |

| Cutter picture |  |

| 5. Thrust motor when you make Galvanized Steel Strip Thickness 0.4-0.6mm  |

|

6.Mould

| Material | High wear-resistant abrasive steel |

| Process treatment | Quenching and tempering, nitriding |

| Mould picture |  |

7.automatic Stacker

Setting out rack 1 set

8. Automatic Unwinder

9. Automatic welding machine

10 spare parts for free

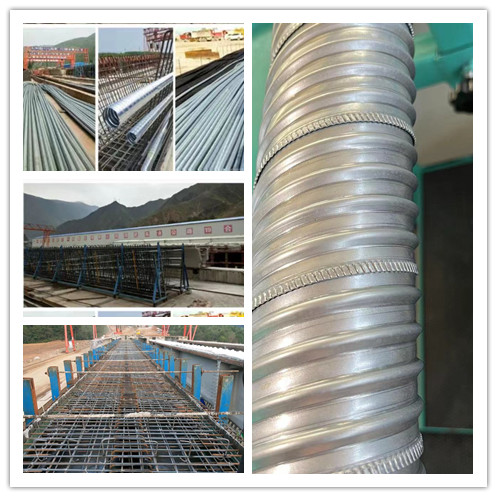

The following is our machines shipment picture

We sell the automatic prestressed metal bellows production equipment to hebei customer

We sell the automatic prestressed metal bellows production equipment to guangxi customer

We sell the automatic prestressed metal bellows production equipment to jiangxi customer

We sell the automatic prestressed metal bellows production equipment to guangzhou customer

We sell the automatic prestressed metal bellows production equipment to anhui customer