HDPE PIPE EXTRUSION LINES

Qingdao cuishi plastic machinery co,ltd started to make the plastic pipe line since 1999 and we have good technical department and our engineers are worked in plastic machinery for 30 years and have rich experience to make the pipe machine

Qingdao cuishi plastic machinery co,ltd started to make the plastic pipe line since 1999 and we have good technical department and our engineers are worked in plastic machinery for 30 years and have rich experience to make the pipe machine

The center height of the whole production line equipment is 1100+-50mm to design and produce

We test 315mm pe pipe line with SDR9 well for our Russia customer

We adopt the SJ75/38 single screw extruder with 600kg/h and with Siemens PLC touch screen system to control the whole production line from auto loader and dryer system and Meter Weight System to control the meter weight and output exactly

The control of the rice heavy machine is 0-10V voltage control, so the control of the host and traction should be controlled by voltage

Configuration:

Plastic automatic loader →Hopper plastic dryer→ Single screw extruder (Mark line extruder)→ Mould and calibrator → Vacuum forming machine → Water cooling tank → Haul off machine → Cutting machine → stacker

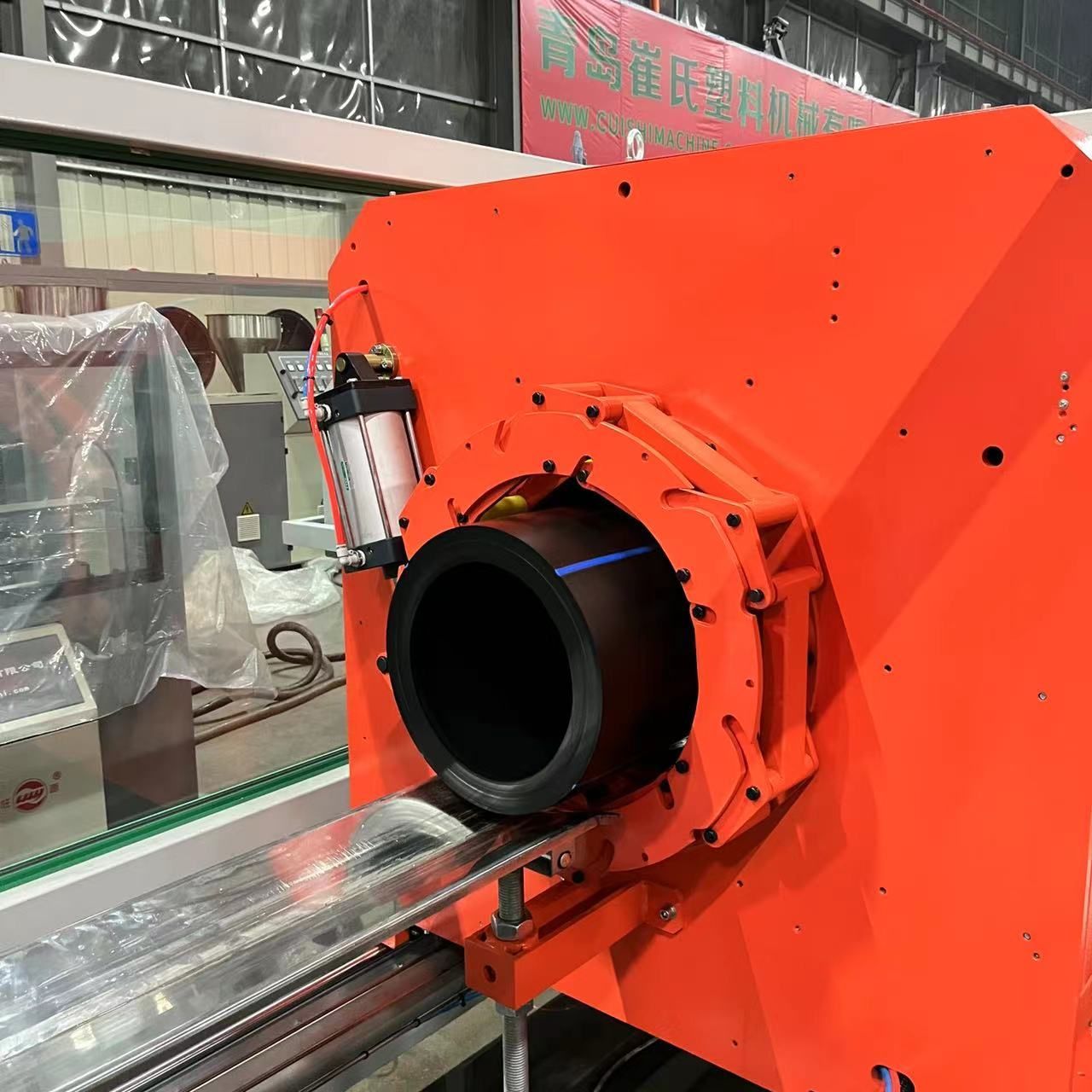

The pipe die head can make from 110-315mm and with 10 zones of mold external heating, 2 zones of internal heating, 220V, 50HZ, total power 35.2KW

Internal heating with 2 zones, 3kw+1.5kw

The specially designed by CUISHI basket die head and spiral die head for the CUISHI series single screw extruder fits well with the CUISHI high speed vacuum calibrator and guarantees the high output with excellent artical quality .

Features:

1. Regardless of material viscosity variation ,widely applicable for HDPE/MDPE,PERT,PP/PPR,PPR-FIBER,PB,PS/ABS and HMW-PE pipe production with reliable processing property .

2. High output but rather low pressure drop and melt temperature

3. Capacious and smooth runner reduces the pipe stress to the minimum

4.High quality cermic heater with long service life

5.Pipe with scratch-free smooth surface finishing

vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

THE HAULING OFF MACHINE

haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the DELTA inverter.

MAIN PARAMETERS

|

Model |

Pipe Diameter |

Extruder |

Output |

Installation Power |

Extruder Power |

|

(mm) |

(kg/h) |

(kw) |

(kw) |

||

|

SJ45 |

16~32 |

SJ45/30 SJ25/25 |

30~60 |

40 |

22 |

|

SJ65 |

20~75 |

SJ65/33 SJ25/25 |

80~120 |

65 |

37 |

|

SJ75 |

50~160 |

SJ75/33 SJ25/25 |

80~150 |

150 |

75 |

|

SJ90 |

75~250 |

SJ90/33 SJ25/25 |

280~350 |

200 |

110 |

|

SJ75 |

160~315 |

SJ75/38 |

550~800 |

280 |

160 |

|

SJ150 |

315~630 |

SJ150/33 SJ30/25 |

550~800 |

420 |

285 |

Dustfree cutter

Its structure is beautiful and practical with glass window design. Cutting process is controlled by PLC, can realize accurately arbitrary length cutting.

Cutting type : knife cutting (no dust)

Clamping method: pneumatic

Clamping device: aluminium clamping device (each size has its own clamping device)

110MM PIPE WINDER