HDPE pipe production line

|

Item |

Description |

Qty |

Fob Qingdao Price |

| HDPE Pipes Production Line(400-1100mm) | |||

|

1 |

Automatic feeding machine |

1sset |

|

|

2 |

Hopper dryer |

1set |

|

|

3 |

Single-Screw Extruder type SJ150/33 |

1 set |

|

|

4 |

Moulds(including calibrators) |

1 set |

|

|

5 |

Marking line co-extruder type SJ30/25 |

1 set |

|

|

6 |

Vacuum calibration tank |

2 set |

|

|

7 |

Extended water spraying cooling tank |

3 set |

|

|

8 |

8-Pedrails Hauling off Machine |

1 set |

|

|

9 |

Planet cutting machine |

1 set |

|

|

10 |

Pipe stacker |

1 set |

|

1 About PE pipe industry

◊ Market research

Polymer, a chain of monomers is versatile which has led to the versatility of the plastic products. The horizon of the plastic products is broad. One of these versatile plastic products is a high density polyethylene pipe which delivers safe and clean water. These pipes with its numerous advantages has benefited the society with advantages such as chemical resistance, corrosion resistance, no toxicity, longer life cycle, better impact strength, light weight, lower installation costs, energy savings etc.

◊ Polyethylene Pipes for Entrepreneurs

The business of an entrepreneur lies on high volume business bringing in a higher net profitability for an entrepreneur.

Monetary gains in terms of net profitability which the entrepreneur aims at, helping the entrepreneurs in deciding on the selection of a new product while entering into a new business forms the major element of a business.

The other elements on which the business lies contributing to a higher net profitability is the higher product mix leading to a higher capacity utilization and the distribution pattern.

Achieving a higher product mix with more number of products which can be produced on a single machinery making the machinery versatile leading to a lesser dependence on a single product would result into minimal risks in business.

New products, new applications, new end uses in high density polyethylene pipe business contributing to the growth of the plastic processing industry bringing in a broadened horizon for the entrepreneurs making it possible for the entrepreneurs to achieve a higher product mix would lead to a higher net profitability.

Versatility of the extruder capable of producing products either using the same polymer or different polymers bringing in a higher growth of the pipe industry would lead to more and more number of new units in the country.

1 Project evaluation

According to your demand for PE (630-800mm) pipe production line, we’d like to recommend our standard PE pipe production line. With less labor, lower power consumption, this scheme can be regarded as high effective, economical, safety and stability. This line can save more energy as the best configuration that matches to your complete project.

1.1 Material characteristics

◊ Based material:

Polyethylene resin

Master Batch

◊ Additive (If need):

Oxidation inhibitor

Ultraviolet ray stabilizer

◊ Material form

All the material should be mixed completely.

A. EQUIPMENT LIST

- 1 set of Automatic feeding machine ZJ-1000

- 1 set of Hopper dryer ZJ-1600

- 1 set of Single-Screw Extruder type SJ 150/33

- Moulds for 400-1100MM

- 1 set of Mark line extruder type SJ30/25

- 2 set of Vacuum calibration tank

- 3 set of extended water spraying cooling tank

- 1 set of 8-pedrails hauling Machine

- 1 set of Planet-cutting machine

- 1 set of Pipe stacker

B. DETAIL TECHNICAL SPECIFICATION OF ABOVE MACHINES

- Automatic feeding machine type ZJ-1000

|

Item |

Description |

Unit |

ZJ-1000 |

| ﹡ working principle: vacuum suction ﹡ automatic start and stop the loading action | |||

|

1 |

Static pressure max. |

Pa |

16000 |

|

2 |

Air flow max. |

mз/min |

4.5 |

|

3 |

Motor power |

kw |

5.5 |

|

4 |

Motor speed |

rpm |

2800 |

|

5 |

Electric power supply required |

/ |

380V 50HZ |

|

6 |

Delivery capacity |

/ |

1000kg/h |

|

7 |

Suction hopper volume |

L |

25 |

|

8 |

Delivery hose dia. |

mm |

50 |

|

9 |

Suction hose dia. |

mm |

60 |

|

10 |

Figure dimension |

mm |

800×5300×1010 |

|

11 |

Weight |

kg |

150 |

- 1 set of Hopper dryer STG-U 1600

| Item | Description | Unit | STG-U1600 |

| ﹡ forceful hot air drying﹡ energy conservation | |||

| 1 | Volume | L |

16000 |

| 2 | Charge Capacity | Kg |

1000 |

| 3 | Air flow | mз/min |

22 |

| 4 | Fan motor power | kw |

1.1 |

| 5 | Electric supply requirement |

380V 50HZ |

|

| 6 | Heater power | kw |

36 |

| 7 | Temperature max. | ℃ |

130 |

| 8 | Precision of temperature control |

±5℃ |

|

| 9 | Material of the barrel |

Stainless steel |

|

| 10 | Plastic-contacting parts material |

Stainless steel |

|

- 1 set of Single-Screw Extruder type SJ 150/33

| ﹡Screw、barrel design and manufacturing absorb European advanced technology

﹡Screw and barrel material:38CrMoAlA,nitriding treated ﹡adopt original famous electric components with high steady running quality . Eg: RKC or Omron temperature controller、Eurotherm DC speed regulator、low-voltage breaker adopts Schneider or Siemens ﹡Gearbox: high torque, low noise, hard gear tooth face dedicated extruder gear box ﹡Self protective system: Over current protective of motor Over pressure protective of screw ﹡Optional control ways: PLC with Siemens touch screen control panels |

||

|

General description |

Main electric elements | DC speed regulator: Eurotherm

Temperature controller: RKC or Omron Contactor: Siemens or Schneider Air-break switch: Siemens or Schineirder Other electric elements: famous brand products |

| Max Output | 850-950kg/h | |

| Connect type of extruder and mould | Bolt connection | |

| Material Feeding

System |

Vacuum feeder | 1 pcs |

| Dryer | 1 pcs | |

| Screw | Diameter(mm) | 150mm |

| L/D | 33/1 | |

| Max Rotating speed(r/min) | 75 | |

| Material | 38CrMoAlA, Nitrogen treated | |

| Heating | Casting aluminum heater with stainless steel outer cover | |

| Heating segments | 9 segments | |

| Heating power | 9.5KW×9 | |

| Barrel | Barrel type | Grooving barrel with water forced cooling feeding part |

| Cooling | Cooling by forceful low noise blower | |

| Cooling air blower power | 0.55 KW×9 | |

| Material | 38CrMoAlA, Nitrogen treated | |

| Drive and

Transmission system |

Main motor power(KW) | 315kw |

| Speed adjusting mode of main motor | DC timing | |

| Rotating speed of main motor (r/min) | 1500r/min | |

| Gear box | High torque, low noise

Hard tooth face Material of gear: 20CrMnTi |

|

Moulds

| Item | Description | Unit | |

| ﹡Absorb European advanced technology﹡Mould material adopts good quality alloy | |||

| 1 | Available Diameters | mm | 400-1100MM |

| 2 | Wall thickness | Mpa | SDR11, SDR17(or according to customer request) |

| 3 | Mould material | / | 40Cr ; high strength alloy; inner surface polished |

| 4 | Material of the calibrator | / | Brass |

5. Marking line co-extruder type SJ30/25

| Item | Description | Unit | SJ30/25 |

| ﹡Screw、barrel design and manufacturing absorb European advanced technology﹡Screw and barrel material:38CrMoAlA,nitriding treated

﹡adopt original famous electric components with high steady running quality |

|||

| 1 | Diameter of the Screw | mm | 30 |

| 2 | L/D | / | 25:1 |

| 3 | Material of the Screw and barrel | / | 38CrMoAl, nitriding treated |

| 4 | Drive motor power | KW | 3 |

| 5 | Speed governor | / | Fuji frequency inverter |

| 6 | Screw and barrel heating | / | Cast aluminum heater |

6. One set of one chamber Vacuum calibration tank CS-I 800

| Item | Description | Unit | CS-1200 |

| ﹡ two segment design is easy for pipe forming and convenient for operation.

﹡ automatic water level control and water temperature control ﹡ electric cabinet with water-proof protection ﹡ forceful concentrated spraying water cooling with good cooling effect ﹡ vacuum pump and water pump adopts good product with durable steady working quality. ﹡ Perfect pipeline design with impurity filter device can keep nozzle unblocked |

|||

| 1 | Length of Vacuum tank | mm | 1500 |

| 2 | Material of the Vacuum tank | / | stainless steel |

| 3 | Cooling Mode | / | Forceful Spray-pouring cooling |

| 4 | Spraying nozzle material | / | ABS |

6-2. one set of one chamber Vacuum calibration tank CS-II 1100

| Item | Description | Unit | CS-500 |

|

|||

| 1 | Length of Vacuum tank | mm | 10500 |

| 2 | Material of the Vacuum tank | / | stainless steel |

| 3 | Cooling Mode | / | Forceful Spray-pouring cooling |

| 4 | Spraying nozzle material | / | ABS |

7. Three set of extended water cooling tank

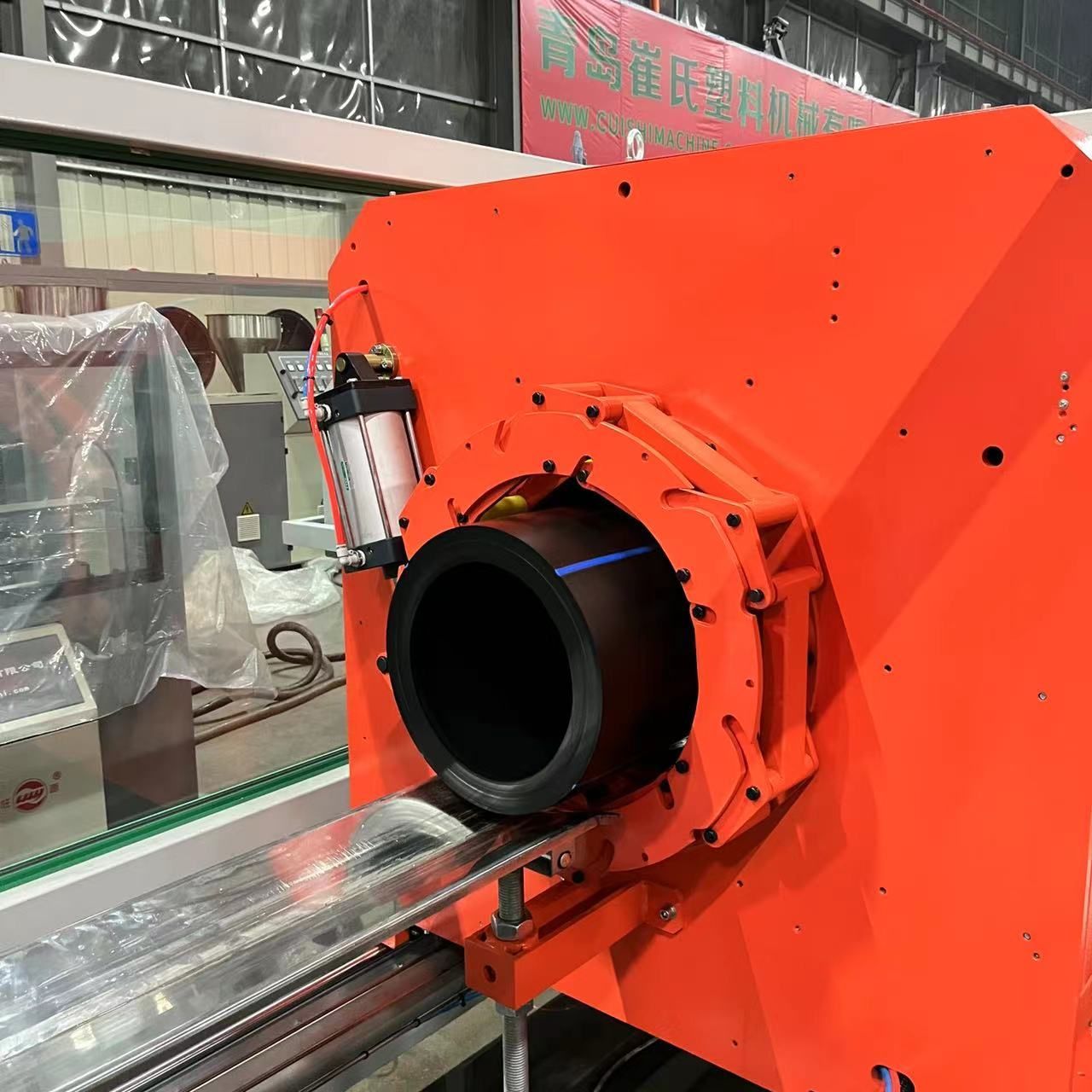

8. 8-Pedrails haul off Machine

| Item | Description | Unit | QY-1100 |

| ﹡8-pedrials haul, steady and powerful hauling ﹡Pneumatic clamping, variable frequency speed adjusting

﹡With imported glass shield |

|||

| 1 | Available diameter | mm | 400-1100 |

| 2 | Available clamping Length | mm | 2500 |

| 3 | Hauling pedrails width | mm | 80 |

9. Planet-Cutting Machine

10. Pipe stacker

| Item | Description | Unit | CS-1100 |

| 1 | Tilting method | / | Pneumatically drive |

| 2 | length | mm | 6000 |

Spare part list (free):

|

No. |

Name |

Qty. |

Use place |

|

1 |

Thermocouple |

5 sets |

extruder |

|

2 |

Rubber block |

15 sets |

Haul-off |

|

3 |

Seal |

10m |

Vacuum tank and spray tank |

|

4 |

Spray nozzle |

20 sets |

Vacuum tank and spray tank |

|

5 |

Heating contactor |

2 sets |

Electric box |

|

6 |

Small circuit breaker |

2 sets |

Electric box |

|

7 |

Extruder screw unload tools |

1 set |

Unload screw |