High Quality Profile Extrusion Line - Configuration list of PVC/WPC profile production equipment – Cuishi

High Quality Profile Extrusion Line - Configuration list of PVC/WPC profile production equipment – Cuishi Detail:

Qingdao Cuishi Plastic Machinery Co.,Ltd

Sales manager : Sevenstars Lucy

Wechat /Whatsapp : +86 15753291269

Email : [email protected] www.cuishimachine.com

DESCRIPTION OF GOODS:

|

Name of Commodity

|

| PVC/WPC door frame production line1 set Double-Screw Extruder – SJSZ65/132

With inovince servo motor with screw loader 1 set vacuum calibration table 1 set hauling off 1 set cutter machine 1 set stacker |

| Door frames sizes for wpc3×2 inch

4×2.5inch 5×3inch 5×3inch |

| SHR500/1000 hot and cold mixer with 75kw inverter |

| SWP450 crusher , 22 kw motor , air delivery system 3kw , output 400-600kg |

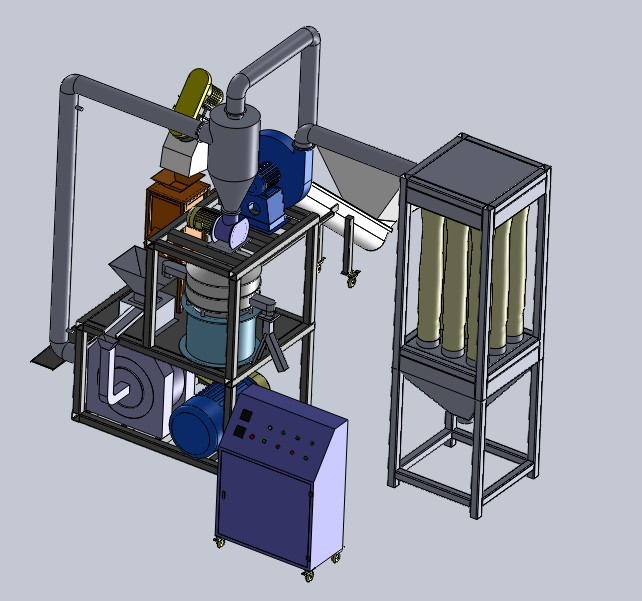

| PVC /WPC pulvertizer 600 type with 55kw motor |

Production technical conditions

1. Adaptive power supply: 380v/3p/50Hz

2. Applicable resin: PVC/WPC + additives

3. Extrusion volume: 300kg / h (max.)

4. Product specification: PVC/WPC door frame profile

5. Production line speed: 0.5m/min

6. Center height of extruder: 1000mm

7. Operation direction: Right to left

8. Installed capacity: 68kW (production energy consumption is about 25kW / h)

2、 Equipment composition

1. SJSZ-65 / 132 twin screw extruder 1 set

2. Zkdj-300 vacuum sizing platform 1 set

3. Sjg-200 crawler tractor 1 set

4. Qg-200 sawing machine (pneumatic automatic cutting) 1 set

5. Fz-6 turntable (made of 6m stainless steel) 1 set

PART I. Technical specification of each machine

1. 65/132 Conical Double Screw Extruder

1.1 servo motor 31KW 1 set

1.2. Variable frequency speed regulation device (produced by Huichuan) 31KW 1 set

diameter 65/132mm Aspect ratio 22:1 texture of material 38CrMoAlA

surface treatment Nitriding, polishing speed 1-60r/min

1) Screw

2) Barrel

texture of material 38CrMoAlA

Internal surface treatment Nitriding, diffractive grinding

Heating mode Cast aluminum heating ring

heating power 18kw Cooling system Barrel fan cooling

Cooling power 180w × three

3) Reducer (jiangchi)

- box material HT200 – gear form Helical gear

- gear material 20CrMnTi – gear surface heat treatment Tooth surface quenching

- cold mode Internal circulating water cooling

4) Drive motor

- mode servo motor – power 31KW

- motor controller frequency control

5) Control appliance – contactor Siemens

- temperature control instrument Delta digital display intelligence

6) Metering feed

- mode Spiral type – motor power: 0.75kw

7) Automatic feeder

- mode Spiral feeding mode – power 1.5kw

WPC profile mould

2.Zkdj-300 vacuum sizing platform 1 set

Unique design, compact structure, advanced cooling mode, high output, stable performance, fast mold change and convenient operation.

1. Two hzb-2.7 vacuum pumps

- motor power: 5.5KW

- vacuum degree: 0-0.09Mpa

- extraction volume: 2.7x 160 m ³/ h

2. Two hisz-125 centrifugal pumps

- motor power: 1.5KW

- flow: 25 m3 / h

Centralized water supply and four position spray (hydraulic spray water supply pipeline system)

3. Sizing range;

4. One forward and backward motor

- model: XWDZ-11-0.75

- motor power: 0.75KW

- transmission mode: Lead screw drive

5. Platform material: 304 stainless steel

3. Sjg-200 crawler tractor 1 set

The traction device is characterized by its compact structure and continuous operation without maintenance.

- traction mode Double track traction

- clamping form Pneumatic clamping

- effective track frame length 2000mm

- traction speed 0.3-6m/min

- drive motor alternating current dynamo

- mode and power 3kw

- motor controller mode Frequency conversion control (Huichuan)

4. Qg-200 sawing machine (pneumatic automatic cutting) 1 set

The length can be precisely determined by using the travel switch, or the adjustable length measuring device can be used for automatic pneumatic clamping and translational cutting.

- mode Saw blade cutting

- clamping mode Pneumatic

- table displacement mode Pneumatic translation

- cutting range 50-200mm

- cutting power: 1.5kw

Product detail pictures:

Related Product Guide:

We thinks what customers think, the urgency of urgency to act in the interests of a customer position of principle, allowing for better quality, lower processing costs, prices are more reasonable, won the new and old customers the support and affirmation for High Quality Profile Extrusion Line - Configuration list of PVC/WPC profile production equipment – Cuishi , The product will supply to all over the world, such as: Lithuania, Cambodia, Israel, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!