New Arrival China Pvc Pipe Production Line - Plastic Cable Protection Spiral Pipe Machine HDPE Spiral Pipe Production Line Machinery – Cuishi

New Arrival China Pvc Pipe Production Line - Plastic Cable Protection Spiral Pipe Machine HDPE Spiral Pipe Production Line Machinery – Cuishi Detail:

Product Description

Qingdao cuishi Plastic machinery Co., LTD is focusing on research and development of the continuous production of PE,PVC corrugated pipe production line manufacturing.The speed we can make from 2.5m-4m.min

We have more than 2000 users in china to make the pipe since 1999

We manufacture complete machine for corrugated post tensioning ducts. Corrugated tubes can be used in many different applications in many different industries. We also supply complete extrusion lines for corrugated pipe for:

Automotive Engine Compartment Cable Protections

Mechanical Engineering Drainage Electrical Ventilators

Plumbing Sport and Leisure and Many More…

The prestressed corrugated pipe use and advantages

In modern architecture, prestressed metal and plastic bellows has been widely used in developed countries such as Britain, France, the United States and Japan. It is light in weight, thin in wall, strong in rigidity, non breaking and non slurry leakage. Because there are obvious concave convex double waves on the surface of the pipe boCS, the joint of the steel pipe is closely embossed, firm and non tripping. After on-site pouring, it has strong contact and binding force with the concrete, forms a complete integration with the concrete, and enhances the seismic performance of the structure. It has excellent functions. Compared with the general solid slab, it has light self weight, large span, small deflection, no column cap, good safety and low comprehensive cost. Therefore, it improves the building clearance and increases the use and sales area. Compared with the existing domestic ordinary beam slab structure, solid beamless slab and unbonded prestressed concrete slab, it saves 5% – 7% of steel, 10% – 30% of concrete and vertical water, electricity, air conditioning, elevator The interior and exterior wall decoration costs 5% – 15%, and has the effect of sound insulation and heat insulation, bringing considerable economic benefits to the owner.

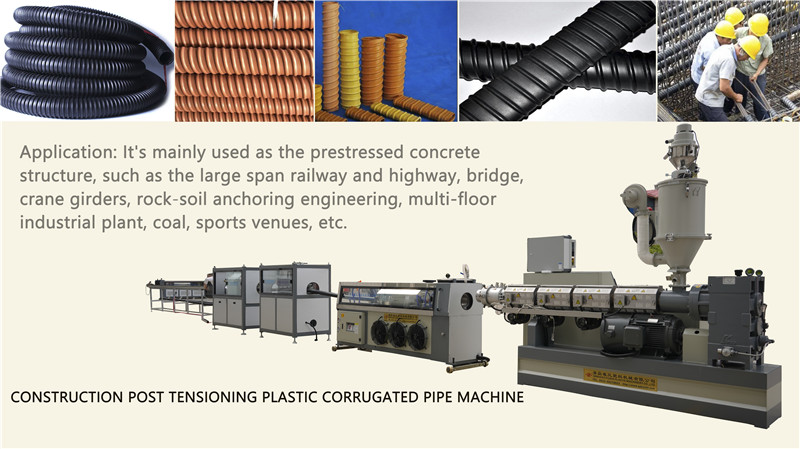

Prestressed metal and plastic bellows are mainly used in highway bridges, railway bridges, construction, water conservancy, electric power and other national key projects.

The prestressed hole forming system composed of bellows and accessories shall meet the needs of post tensioned prestressed grouting; For the connection between pipes, in addition to thermal welding connection, special sealing connection device shall also be provided. This device shall be equipped with exhaust, drainage, slurry discharge and slurry discharge pipe with observation effect in the process of duct grouting, so as to meet the needs of pressure grouting or vacuum assisted grouting.

This kind of spiral corrugated pipe is high temperature resistance, corrosion resistance, wear resistance, high strength, widely used in bridge prestressed pipe, underground cable threading sheath, etc.

Also the prestressed corrugated pipe machine can make the flat pipe by oven By changing the pipe calibration , it can also produce the PE carton spiral pipe machine, But you need to add the pipe winder for embedded cables

The machine inclued: SJ – 75/30 type single screw extruder, die head mold, forming machine, cutting machine, winder system or stacking machine. Product material is PVC/PE, optimal pipe diameter range for Φ 50-200 mm Φ. Simple operation, good integrity, continuous and stable production, low noise, high efficiency, long service life.

The spiral corrugated pipe product has special spiral physical structure, the pipe material mechanical performance is good, the compressive strength, pipe buried under deformation, inner spiral uniform cable around the cooling efficiency and effectively protect the security of the cable.

Also the pe sprial pipe machine by changing the sleeve can produce the pe carbon sprial pipe machine

Qingdao HDPE Sprial Corrugated Pipe Extruder Machine With Good Price

1.Single Screw Extruder we supply SJ65 , SJ70,SJ80, SJ90, SJ120 series according to output

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality PIPE extrusion.

Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel >940, the surface of screw is chromeplated Feeding bush with water cooling system

forming Machine , we design the vacuum forming tank with the chiller inside to control the water temperature within 10 degree to cool fast and improve the output

Made stainless steel, it adopts vacuum and water spraying system

It also match the oven system can produce the flat corrugated pipe machine

Haul off and cutter system

It use rubber block materials to do pipe pulling, the pulling motors are controlled by inverter. Cutter is saw cutting way.

High quality pipe haul off machine price

1) It can be suitable for plastic pipes(<160mm).

2) In general, it is used together with other auxiliary equipments in extrusion line.

3) Adopting stepless speed regulation,large range of speed regulation.

4) Stable drawing speed.

5) Low noise.

6) Compact structure,exquisite appearance.

7) Easy to install and also control conveniently.

Dust free Cutting machine Plastic Pipe cutter Machine plastic saw cutter

Some parameter for your reference

|

Model |

Range of traction tubing (mm) |

Number of traction belts (mm) |

Power of drive motor (kw) |

Peak traction (N) |

Max pulling length (mm) |

Max.speed (m/min) |

|

CS32 |

6-32 |

2 |

2×0.75 |

3000 |

600 |

30 |

|

CS75 |

16-75 |

2 |

2×1.1 |

10000 |

1000 |

15 |

|

CS160 |

20-160 |

2 |

2×1.5 |

15000 |

1500 |

10 |

|

CS 250 |

50-250 |

3 |

4 |

20000 |

1500 |

3.5 |

|

CS 315 |

75-315 |

4 |

5.5 |

25000 |

1500 |

3 |

|

CS 450A |

110-450 |

4 |

5.5 |

25000 |

1600 |

2 |

|

CS 450B |

110-450 |

4 |

5.5 |

30000 |

2200 |

1.2 |

|

CS 630A |

200-630 |

6 |

7.5 |

35000 |

1600 |

1.4 |

|

CS 630B |

200-630 |

6 |

7.5 |

40000 |

2500 |

0.9 |

|

CS 800 |

315-800 |

8 |

11 |

60000 |

2500 |

0.7 |

Application

1)The cutting of the products do not produce chips, and cut sections smoothing products, thus saving products, raw materials, but also conducive to products with the corresponding pipes connector.

2)The cutting of the products at the line can be carried out simulaneously at any time, you can not cut the production line at any time of sampling.

3)Cutting the process smooth, no noise.

4)High automation, high cutting quantity and appearance is beautiful.

Main Techical Standards

| Model | WQG75 | WQG110 | WQG160 |

| Motor power | 1.1kw | 1.5kw | 1.5kw |

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Cutting blade | 55mm | 75mm | 85mm |

| Cutting length | 600mm | 700mm | 700mm |

| Cutting demension | 20-75 | 32-110 | 50-160 |

| Apperance | 1700mmX1000mmX1400mm | 2200mmX1000mmX1400mm | 2500mmX1100mmX1600mm |

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for New Arrival China Pvc Pipe Production Line - Plastic Cable Protection Spiral Pipe Machine HDPE Spiral Pipe Production Line Machinery – Cuishi , The product will supply to all over the world, such as: Colombia, British, Manchester, At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.