OEM China Cable Protection Tube Machine - Plastic MPP Electric cable Wire conduit pipe machine extrusion making machine manufacturer – Cuishi

OEM China Cable Protection Tube Machine - Plastic MPP Electric cable Wire conduit pipe machine extrusion making machine manufacturer – Cuishi Detail:

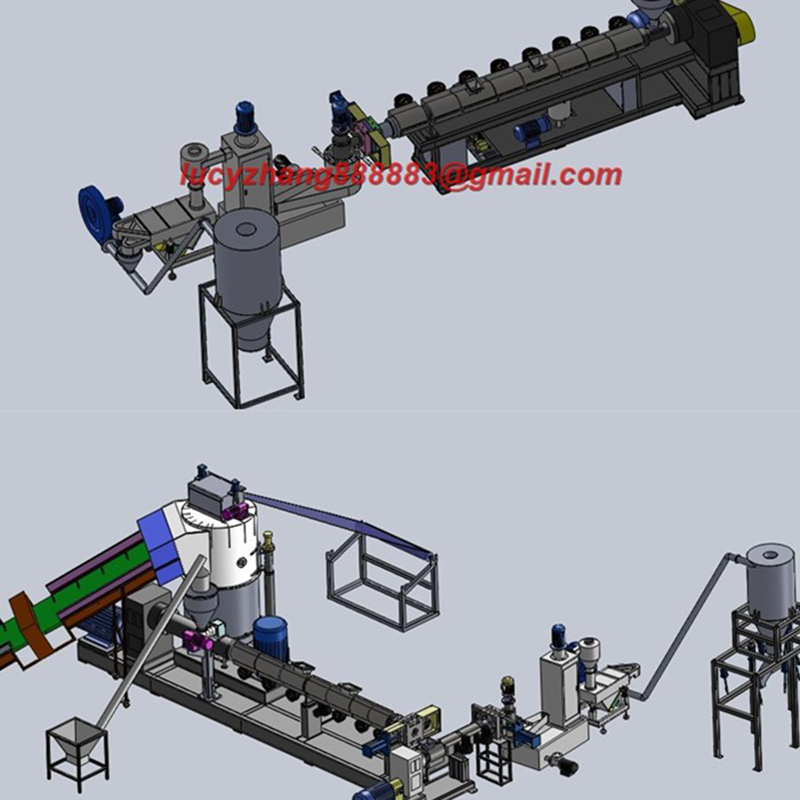

Plastic MPP electric pipe production line

Plastic tube electrical wire protection pipe power cable conduit MPP power pipe making machine

MPP pipe making machine cost price electrical pipe making machine

Plastic MPP Electric cable Wire conduit pipe machine extrusion making machine manufacturer

Introduction :

MPP electric protection pipe is made of modified polychloropropene, which can be divided into excavation and non-excavation. It can be widely used in municipal, electric power, telecommunications, gas pipes, tap water, etc.

Electrical Conduit machine Plastic Extruder machine PVC MPP Pipe machine with factory price China

| No. | Name | Model | Number |

| 1 | Single screw extruder | SJ90/33 | 1set |

| 2 | Hopper dryer | 200 | 1set |

| 3 | Powder feeder | 700 | 1set |

| 4 | MPP Extrusion die | Ф110-Ф250 | 1set |

| 5 | Vacuum sizing box | SGD250 | 1set |

| 6 | Spray cooling box | SGL250 | 2sets |

| 7 | Three claw haul-off machine | SGQ250 | 1set |

| 8 | Dust-free cutter | SGG250 | 1set |

| 9 | Stacker | 250 | 1set |

Plastic MPP Electric cable Wire conduit pipe machine extrusion making machine manufacturer

Plastic MPP electric pipe production line

Plastic tube electrical wire protection pipe power cable conduit MPP power pipe making machine

MPP pipe making machine cost price electrical pipe making machine

Plastic MPP Electric cable Wire conduit pipe machine extrusion making machine manufacturer

Introduction :

MPP electric protection pipe is made of modified polychloropropene, which can be divided into excavation and non-excavation. It can be widely used in municipal, electric power, telecommunications, gas pipes, tap water, etc.

Electrical Conduit machine Plastic Extruder machine PVC MPP Pipe machine with factory price China

| No. | Name | Model | Number |

| 1 | Single screw extruder | SJ90/33 | 1set |

| 2 | Hopper dryer | 200 | 1set |

| 3 | Powder feeder | 700 | 1set |

| 4 | MPP Extrusion die | Ф110-Ф250 | 1set |

| 5 | Vacuum sizing box | SGD250 | 1set |

| 6 | Spray cooling box | SGL250 | 2sets |

| 7 | Three claw haul-off machine | SGQ250 | 1set |

| 8 | Dust-free cutter | SGG250 | 1set |

| 9 | Stacker | 250 | 1set |

SJ-75/33 SINGLE SCREW EXTRUDER for inner layer 1SET

1.1 screw diameter: 75mm;

1.2 length diameter ratio of screw: 33:1;

1.3 screw speed: 11-110r / min;

1.4 material of screw and barrel: 38CrMoAlA, nitriding and grinding;

1.5 driving power: 90KW, AC motor

1.6 screw structure: high efficiency barrier screw with special mixing section, which greatly improves the plasticization quality and output;

1.7 barrel structure: the asymmetric slotted barrel design is adopted, and the feed inlet is equipped with a water cooling system with automatic temperature control to double the conveying efficiency of the feed section;

1.8 reduction gearbox: the reduction gearbox adopts vertical structure, and the cooling mode is forced circulating oil cooling, with circulating water cooling system. High torque, low noise, hard tooth surface gear, gear grinding process, plus heavy thrust bearing;

1.9 automatic feeder and dryer: imported from Taiwan Xinyi. The automatic feeder is of inductive design, with a conveying capacity of 500 kg / h and a shortage alarm function. The dryer adopts the integrated design of drying and material storage, automatic temperature control and intelligent display, with a hopper volume of 200L and full stainless steel lining;

2. PE PP pipe extrusion mould 110-250mm

Material: 45 steel, forging, quenching and tempering, etc. the hard chromium plating process, wear resistance, corrosion resistance, high strength precision, high stability, long service life.

PE pipe extrusion line

50-250mm PE Pipe Extrusion machine is mainly used for producing agricultural irrigation pipe, gas supplying pipe, water supplying pipe, cable protection pipe etc. The pipe has some excellent features such as low temperature impact resistance, reliable connection, good stress crack resistance, good chemical resistance, good wear resistance, long using life, etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise, and ultrasonic thickness indicator can be assembled according to customer’s demand to ascend the precise of the pipes . Turnkey solution can be provided, like laser printer crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

Process Flow:

Raw material+ Master Batches → Mixing → Vacuum Feeder →Plastic Hopper Drier→ Single Screw Extruder →Co-extruder for color string & Multi Layers → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank → Haul-off → No Dust Cutter → Single Winder or Stacker → Final Product Inspecting &Packing

3. Pipe vacuum cooling tank

Plastic pe ppr pipes stainless steel vacuum sizing calibrator tank with central drain system

Plastic pe ppr pipes stainless steel vacuum sizing calibrator tank with central drain system

Vacuum calibration tank is one important stage of plastic pipe extrusion lines for PC, PE, PP, PVC.

Calibration tank adopts vacuum to calibrate the pipes at defined diameter and also avoids pipe to cause ellipse shape while producing.

Also pipes and calibrating sleeves are cooled effectively by nozzles which are inside the tanks for PC,PE,PP,PVC pipe lines.

Features:

1. Optimized design table,tank and water pipe system made from stainless steel.

2. Water pipe system and vacuum system stablity and adjustable.

3. Vacuum forming table,tank, can be adjustable in 3D direction.

| Model | CS63 | CS125 | CS250 | CS450 | CS800 |

| Pipe Diameter(mm) | 10-63 | 50-125 | 63-250 | 110-450 | 500-800 |

| Length of vacuum tank | 6000 | 6000 | 6000 | 6000 | 6000 |

| Water pump(KW) | 1* 3kw | 1* 4kw | 1* 5.5kw | 2* 5.5kw | 2* 5.5kw |

| Vacuum pump(KW) | 1* 3kw | 1* 3kw | 1* 4kw | 2*4kw | 2*4kw |

4. Spraying cooling tank

5. Three caterpillar hauling off machine

6. Non-dust cutter machine

This PPR PP PE Pipe Machine HDPE Pipe Extrusion Machine Plastic Pipe Lline which have excellent stiffness and flexibility, heat resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage, and so on. So, it is a preferred gas and water pipe for ductwork system between city and its suburb, Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

| odel number | Pipe diameter (mm) | Max output (kg/hr) | Production rate (m/min) | Extruder model | Installation power | Layout dimension |

| PE16/63 | 16-63 | 150 | 1-15 | SJ65/30 | 85kw | 35x3x2m |

| PE20/110 | 20-110 | 200 | 1.2-12 | SJ65/33 | 110kw | 38×3.1×2.2m |

| PE50/160 | 50-160 | 350 | 0.6-8 | SJ75/33 | 125kw | 38×3.1×2.2m |

| PE75/250 | 75-250 | 350 | 0.5-4 | SJ75/33 | 180kw | 40×3.2×2.4m |

plastic non-dust cutter/dust-free cutter/plastic cutting machine

It is mainly used in cutting plastic pipe profile which is transferred by haull-off according to the demand cutting.

Product Description

No Dust Cutter/plastic cutter

It is mainly used in cutting plastic pipe profile which is transferred by haull-off according to the demand cutting.

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for OEM China Cable Protection Tube Machine - Plastic MPP Electric cable Wire conduit pipe machine extrusion making machine manufacturer – Cuishi , The product will supply to all over the world, such as: Amsterdam, Albania, Bangladesh, Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!