OEM Customized Cable Protection Tube Machinery – Double wall corrugated pipe extrusion machine – Cuishi

OEM Customized Cable Protection Tube Machinery – Double wall corrugated pipe extrusion machine – Cuishi Detail:

DESCRIPTION OF GOODS:

|

Name of Commodity

|

Quantity

|

| SINGLE /DOUBLE wall corrugated pipe line

1.SJ90 single screw extruder 2.Auto screw loader 3.Die head 4.90 pairs mould 110mm 5.calibration table 6.Cutter machine |

1 set |

| FOB qingdao USD |

1.PAYMENT: 30% down-payment by T/T, the other 70% by T/T before shipment

single wall corrugated pipe production line

Please check test video by youtube

Project evaluation

1.1 Basic Infrastructure (Provided by customer)

a. Electricity network: can adjustable according to your local voltage standard.

b. Wire/cables: wires/cables from customer’s general control cabinet to the main control cabinet for PVC corrugated pipe production line; all electrical cable from the main control cabinet to each machine.

c. Water supply: main water pipe line supply and water pipes to machines

d. Compressed air supply: necessary compressed air for mould, forming machine, winder

e: lubrication oil: for reducer gearbox

1.2 Energy consumption:

a. Electricity requirement

Total Install power: 70KW.

Actual power consumption percentage: 80% of total power

b. Labor requirement

Max. Qty. of labors: 1 person

c: compressed air requirement: 0.4Mpa-0.8Mpa

PART I SPECIFICATION AND PRICE

A SYSTEM CONFIGURATION OF THE PRODUCTION LINE:

• 1 set of Vacuum feeding machine type ZK-300

• 1 set of Hopper dryer type GZ-50

• 1 set of Single screw extruder type SJ 90

• 1 set of Die head & forming machine (include 1set forming mould)

• 1 set of cutter

B DETAIL TECHNICAL PARAMETERS OF THE ABOVE CONFIGURATIONS

1. Vacuum feeding machine

|

Item |

Description |

Unit |

ZK-300 |

|

1 |

Material |

|

Stainless steel |

|

2 |

Loading capacity |

kg/h |

200 |

|

3 |

Motor power |

KW |

1.5 |

2. Hopper dryer

| Item | Description |

Unit |

GZ-50 |

| 1 | Material |

|

Stainless steel |

| 2 | Charge Capacity |

Kg |

100 |

| 3 | Heating power |

KW |

4 |

| 4 | Fan power |

W |

180 |

| 5 | Error |

|

±1℃ |

3. SJ90 Single screw extruder

| Item | Description |

Unit |

SJ90/30 |

| 1 | Screw diameter |

mm |

90 |

| 2 | L: D |

|

25;1 |

| 3 | Motor power |

KW |

AC30 |

| 4 | Brand motor |

|

Kaiyuan |

| 5 | Motor speed adjusting mode |

|

Frequency conversion |

| 6 | Inverter |

|

Holip |

| 8 | Extrusion output |

Kg/h |

300kg/h |

| 9 | Material of screw and barrel |

|

38CrMoAlA,Nitrogen treated |

| 10 | Nitrogen depth |

mm |

0.5-0.8 |

| 11 | Heating power |

KW |

4 zones, 14kw |

| 12 | Cooling power |

KW |

4 zones, 250w×4 |

| 13 | Gear box |

|

Hard gear surface, low noise design |

4. Die head & forming machine & forming mould

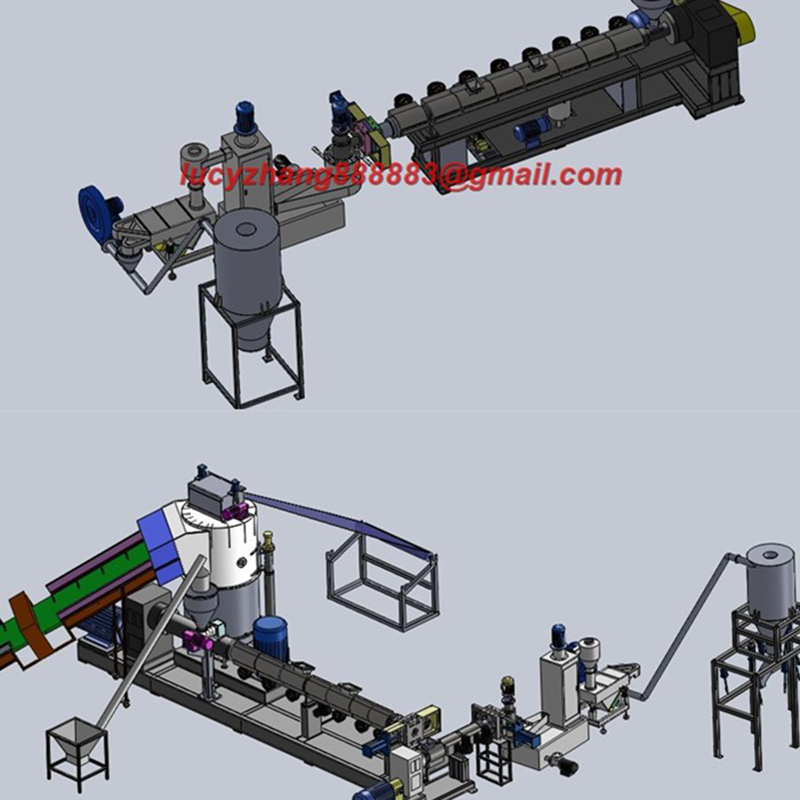

Product detail pictures:

Related Product Guide:

We are commitment to offer you the aggressive price tag ,exceptional products and solutions high-quality, as well as fast delivery for OEM Customized Cable Protection Tube Machinery – Double wall corrugated pipe extrusion machine – Cuishi , The product will supply to all over the world, such as: Luxemburg, Bolivia, British, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!