OEM manufacturer Cable Protection Tube Production Line - Plastic corrugated flexible pipe making machine – Cuishi

OEM manufacturer Cable Protection Tube Production Line - Plastic corrugated flexible pipe making machine – Cuishi Detail:

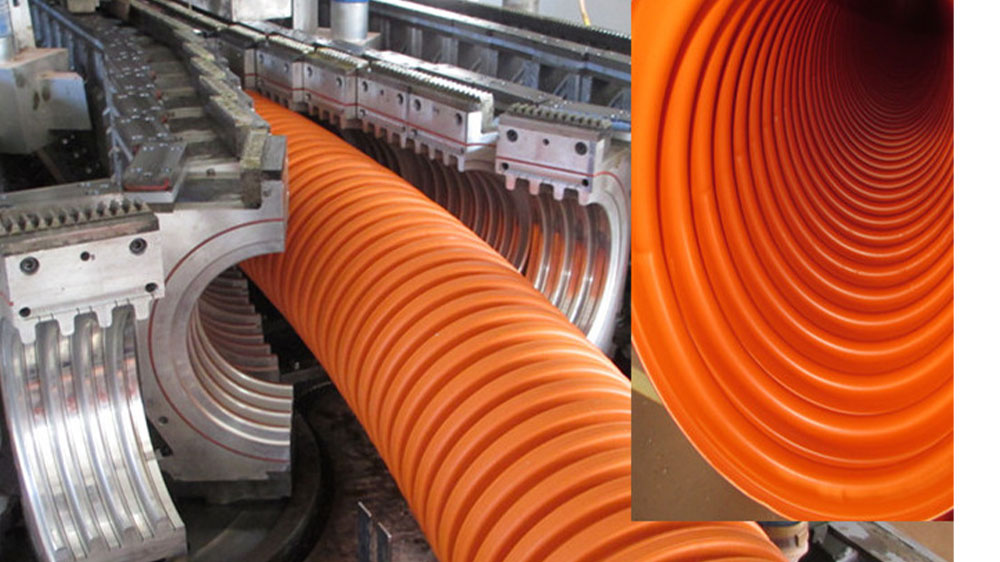

plastic single wall corrugated pipe extrusion line can produce PP/PE/PVC/EVA/PA corrugated pipe.Mould Chain adopts gear transmission,base plate adopts water cooling,mould adopts air cooling.

Corrugated pipe produced by our machine has the features of high production speed,even corrugated shape,straight pipe seam,and smooth surface. By equipped with vacuum pump and vacuum type mould,it can produce different use corrugated pipe with joint(wash basin drain pipe,air conditioner pipe,hookah pipe etc.)

Extrusion line for the production of single-wall and double wall corrugated tubes and pipes made of PE, PP, PVC, PA, EVA, PVDF, TPE etc.

Main Technical Parameter—Single Wall Corrugated Pipe Make Machine:

| Extruder Model | SJ45 | SJ65 |

| Screw diameter (mm) | 45 | 65 |

| Ration of L/D | 28-33:1 | 28-33:1 |

| Pipe diameter range | 9-32 | 32-110 |

| Pairs of modules | 42 (50) | 50 |

| Line speed (m/min) | 3-15 | 3-15 |

| Module cooling way | Air-cooled | Air-cooled |

| Pipe cooling way | Air-cooled | Air-cooled |

| Total install powder (kw) | 50 | 70 |

Main applications:

Building industry: electrical conduit & sanitary hose duct/flexible pipe for siphon, PP-PE-PVC-PA

Automotive industry: Fuel line pipe & wiring harness tubing, PP-PA6-PA11-PA12-PA612

Medical industry: breathing tubes, LLDPE,EVA

The range includes: Water cooling corrugator, Blow forming system corrugator, Vacuum forming system corrugator, Sequential mode corrugator, Variable Chain Length corrugator.

I: features of plastic corrugation pipe production machine

1. PP/PE/PA/PVC/EVA production line can be used to produce single-wall corrugated pipes.

2. Plastic single-wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility, etc. They are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc.

3.Plastic single-wall corrugated pipe production line developed by our company adopts gears to run moulds and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall. These corrugated pipes are especially used as wires of the up-market cars.

II: process of plastic corrugation pipe production machine

loader→Single screw extruder→Die→Forming moulds→Water tank(optional)→Haul off and cutter(optional)→Double working-station winder

III: material of plastic corrugation pipe production machine

PVC PP PA PE EVA

IV: application of corrugated pipe

auto wire,electric thread-passing pipes,circuit of machine tool

protective pipes of lamps and lanterns wire,tubes of air conditioner and washing machine, etc.

technical parameter of plastic corrugation pipe production machine

With special aluminum alloy mould bolck with anti-adhereing treatment, cooling air, cooling water and vacuum channel inside of mould block ensure good forming structure of pipe and speed.

Special structure die make the thickness of the interior and exterior wall even, and stable molding.In addition, the thickness of interior and exterior can be adjusted.

With special and accurate forming module;Cooling air and water system guarantee the production speed fast.With belling inline system.

| Pipe diameter range | 4.5mm-12mm | 9mm-32mm | 12mm-63mm | 32mm-110mm | 50mm-160mm |

| Model of extruder | SJ45 | SJ50 | SJ65 | SJ75 | SJ90 |

| Production capacity | 20-30kg/h | 40-50kg/h | 60-70kg/h | 70-90kg/h | 100-120KG/H |

| Power of extruder | 7.5kw | 15kw | 30kw | 37kw | 55KW |

| Power of forming machine | 1.1kw | 1.5kw | 4kw | 4kw | 4KW |

| Pairs of modules | 42pairs | 50pairs | 50pairs | 72pairs | 72pairs |

| Cooling mode | Wind&Water cooling | Wind&Water cooling | Wind&Water cooling | Wind&Water cooling | Wind&Water cooling |

| Production speed | 6-10m/min | 8-12m/min | 8-12m/min | 2-6m/min | 2-6m/min |

| Main machine model | SJ-45 | SJ-65 | SJ-65 |

| Pipe diameter range (mm) | 4.5-9 | 9-32 | 16-50 |

| Main machine L/D | 30:1 | 28:1 | 33:1 |

| Production capacity (kg/h) | 30 | 60 | 100 |

| Main motor power (kw) | 4 | 15 | 22 |

| Molding machine power (kw) | 1.1 | 1.5 | 2.2 |

| Pairs of modules | 38 | 72 | 90 |

| Production speed (m/min) | 6-10m.min | 25m/min | 30m/min |

| Cooling mode | Wind and water cooling | ||

| Metering mode | Inducting mode | ||

| Coiling machine mode | Motor-driven, manually-operated | ||

SJ-65 PE PP Single-wall Corrugated Pipe Extrusion Line

| Service condition | 380-/3Phase/50HZ |

| Material : | PVC/PP/PE |

| Pipe range : | 16-23mm |

Single-Screw Extruder of SJ—65/30:

| Speed frequency regulator | |

| Screw | 1).Screw diameter : 65mm2).The length and diameter ratio of screw : 30:13).Material of screw: 38CrMoALA,under nitrogen treatment4).The depth of nitrogen layer of screw: 0.4-0.6mm,hardness: HV>740 |

| Barrel | 1).The material of barrel: 38CrMoALA,under nitrogen treatmentl .The depth of nitrogen layer of barrel:0.5-0.7mm, hardness: HV>9403).Barrel heating : 4 heating section ,Material of heating circle :stainless steelHeating power : 6kw*4 sections4).Barrel cooling:4 cooling section,Cooling power:0.18kw*4sections (fan blower ) |

| Motor | Driving motor power : 22kw |

| The capacity of extruder | 80kg/h |

| Auto material loading machinery | |

| Reduction gearbox | 1).Speed reducer is of hard tooth surface2).Material of gear is 20CrMoTi under nitrogen, quenching and grinding treatment.3).Equipped with outer cooling device.The device has strong loading capacity, stable transmission , low noise and high efficiency, etc. |

| Die head | ||

| 1 | Die head material | 40Cr |

| 2 | Inner structure | Spiral type |

| 3 | Melt pressure meter | Equip with a pressure meter to monitor the melt pressure in the die head |

| Forming machine & forming mould 16 and 23mm two sizes .  |

||

| 1 | Material of forming mould | 40Cr, nitrogen treated |

| 2 | Forming mould | 1 set |

| 3 | Quantity of mould block | 90 pairs |

| 4 | Forming machine type | Horizontal type |

| 5 | Forming mould moving way | Circle |

| 6 | Drive motor power | 3kw |

| 7 | Inverter | DELTA |

| 8 | Cooling way | Air cooling |

| 9 | Power of blower | 85w×5sets |

Product detail pictures:

Related Product Guide:

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for OEM manufacturer Cable Protection Tube Production Line - Plastic corrugated flexible pipe making machine – Cuishi , The product will supply to all over the world, such as: Sevilla, Spain, Sudan, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.