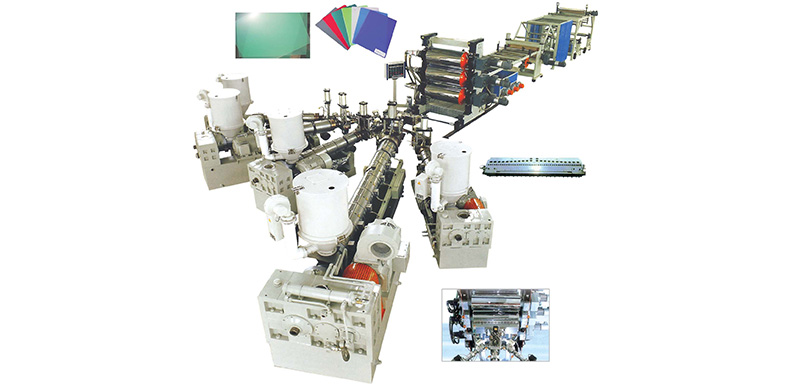

PE PP ABS PMMA sheet production line

Description:

This production line consists of single screw plastic extruder, vacuum automatic feeding unit, dehumidifiers drying hopper, sheet die, 3 roller-ray unit, heating and leveling unit, roll cooling unit, edge cutting unit, traction, shearing unit, roller conveyor unit. With the characteristics of compact structure, superior performance, Screw and barrel optimized design and use of high-performance alloy 38CrMoAiA professional processing which ensure that the whole production line uniform plastics hand stable extrusion, high yield, long life and other advantages. The barrel uses casting aluminum heater heating, wind cooling and precise electronic temperature control instrument; Precise sizing and roller-ray unit to adjust the template good shape; Cutting unit adopt the fixed-length cutting to ensure the accurate length.

Applications:

PE/PP/ABS Single and Multi-layer Sheet is mainly applies to medical appliance parts, sealing, cutting board, widely used in chemical industry, machinery, electric power, clothing, packaging, and food industries, in gas transportation, water supply, water drainage, agricultural irrigation, and oil fields and post and communication, and other fields, especially in the gas transport to be universal application.

Superior Quality PE PP PVC ABS PS Sheet Board Making Machine Production Line

Production Line Composition

Single screw or double screw extruder, screen changer and mould, three roller calender, cooling bracket, haul off machine, transverse cutting machine, auto-stacker (or winder).

Advantages

Absorbing the international advanced technology and crafts, we have developed these PE/PP/PVC/ ABS/ PS/PC/PMMA board sheet production lines, which is mainly used to produce PE/PP/PVC/ ABS/ PS/PC/PMMA board sheet with the thickness 0.35-60mm, width 500-3000mm.

Parameter

All the parts and components of the production line are from world famous brand, combined with our company’s years of experience and mature technology in producing the board (sheet) machines, make the machine is more reliable and perfect.

Application scenarios:

1.PP thick board

PP thick board can be widely used in chemical industry, food industry, anti-corrosion industry, purification industry, and environmental protection equipment production industry.

2. PE thick board

PP thick board is widely used in chemical, electric power and other industries, and HDPE sheets can also be used as engineering plastics in machinery, chemical and other equipment, and are widely used in the manufacture of ice hockey rink wall panels.

3. ABS thick board

ABS thick board is widely used in home appliances, electronics, packaging, medical equipment and other fields.

4.PS board sheet

PS board sheet, PS co-extruded two-color sheet, PS board sheet are used in construction, advertising, transportation, medicine, civil goods, industry, lighting, home furnishing, etc.

5. PC board

PC,board,widely used in construction, engineering and decoration, etc.

6. PMMA acrylic board

PMMA acrylic board is widely used in refrigerators, air conditioners, advertising, construction, environmental protection chemicals, bathroom and other fields.

7. PVC sheet/board

Wall panel decoration, Blister products and so on.

Specifications:

| Screw drive motor power | 30-315kw |

| Screw diameter | 45-150mm |

| Screw L/D ratio | 33/1-38/1 |

| Max screw speed | 110rpm |

| Max extruding product capacity | 30-600kg/h |

| Max production line speed | 10m/min |

| Products width | 600-2500mm |

| Products thickness | 0.6-20mm |

Equipment lists

|

NO |

Machine Name |

QTY |

|

1 |

Conical double screw extruder or Single screw extruder |

1 set |

|

2 |

metering pump and screen changer |

1 set |

|

3 |

Mould |

1 set |

|

4 |

Three roller calender machine |

1 set |

|

5 |

Temperature Control for calender |

1 set |

|

6 |

Cooling bracket ,edge cutting device |

1 set |

|

7 |

Haul-off machine |

1 set |

|

8 |

Auto- Stacker or Double station winder |

1 set |

|

9 |

Electrical control part |

1 set |

|

NO |

Machine Name |

QTY |

|

1 |

Conical double screw extruder or Single screw extruder |

1 set |

|

2 |

metering pump and screen changer |

1 set |

|

3 |

Mould |

1 set |

|

4 |

Three roller calender machine |

1 set |

|

5 |

Temperature Control for calender |

1 set |

|

6 |

Cooling bracket ,edge cutting device |

1 set |

|

7 |

Haul-off machine |

1 set |

|

8 |

Auto- Stacker or Double station winder |

1 set |

|

9 |

Electrical control part |

1 set |

Screw: Big output & L/D ratio. Two stage unique design effects, with low temperature plastication concept.

Barrel: barrel is made of special steel alloy, and is equipped with aluminum thermal foil with air cooling system.

Gearbox: gears are made of steel alloy with heat treatment and are finished with surface precision grinding. By using oil injection cooling system, it reduces noise when operating under high RPM and enhances the life span of gears.

Motor: AC motor, selected famous brand products. Controlled by Omron Inverter.

Control system: Adopt selected high quality and famous brand products from Europe, and Japan manufactures. Machine works more stable and longer working-period.

| Model | SJ-90/33 |

| Extrude central height | 1000mm |

| Max. output | 300kg/h |

| High efficiency screw | |

| Diameter | 90mm |

| L/D | 33:1 |

| Material | 38CrMoAlA |

| Surface Treatment | Nitrided and Polished |

| Screw rotation speed | 20~116r/min |

| Barrel screw | High-speed new design screw |

| Barrel | |

| Material | 38CrMoAlA |

| Inner Surface treatment | Nitrided, ground |

| Heating method | By ceramic |

| Heating control zones | 6zones |

| Heating power | 36KW |

| Cooling system | By blower fan |

| Cooling zones | 6zones |

| Cooling power | 0.25KW*6 |

| Gearbox | |

| Material of the house | QT200 |

| Gear type | Helical gears |

| Material of the gear | 20CrMnTi |

| Heat treatment of the gear surface | Quenching |

| Material of the axes bearings | 40CrImported high quality bearing |

| Feeding block | |

| Material | Q235 |

| Method | Water circled cooling system |

| Automatic feeder | |

| Method | With vacuum suction method |

| Max transporting quantity | 500kg/h |

| Driving motor | |

| Method | AC motor, 90KW |

| Control system | Omron AC frequency converser |

| Overall dimension(L x W x H) | 3650mm x 600mm x 2800mm |

| Weight | 3000kg |

Three roller Calender and side cutter One set

| Product Width | mm | 1220 | |

| Ready products thickness, or gap | Min. | mm | 0.2 |

| Max. | mm | 1.0 | |

| Roller diameter | Upper roller, sup | mm | Ø400 |

| Middle roller, med | mm | Ø400 | |

| Bottom roller, inf | mm | Ø315 | |

| Roller length | mm | 1300 | |

| The thickness of chrome surface | mm | 0.1- 0.12 | |

| Surface chrome conditions | class | 12 | |

| No. of rollers | Pcs | 3 | |

| Max. Linear speed | m/min | 15 | |

| Driving motor power | kw | 2.2 | |

| Driving motor quantity | Pcs | 3 | |

| Moving motor power | kw | 0.75 | |

| Max. elevating dist. Of upperor bottom roller | mm | 50 |