PP Construction Template Extruder Machine / PP Hollow Sheet Board Construction Formwork Building Template Extrusion Line

Plastic hollow pp sheet extrusion machine PP construction building board extrusion line PP hollow bard extrusion machine line

PP construction template extrusion line plastic formwork board making machine

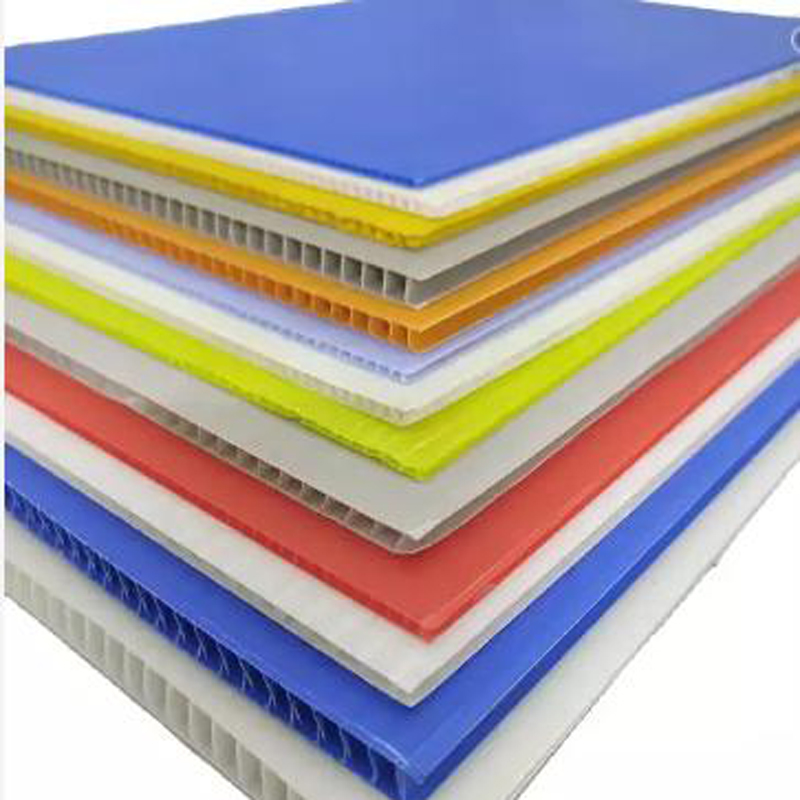

The production line can use PP raw materials and adopt a single-screw extruder to produce three-layers hollow sheets. The quality and specifications of the produced plates meet the requirements of the demanding company.Pp Hollow plastic formwork is a kind of energy-saving and green environmental protection product, pp plastic combined with macromolecule nano-technology. Plastic formwork is a new product after wood formwork, composite steel formwork, bamboo-wood bonding formwork and all-steel large formwork. Hollow plastic formwork is energy saving and environmental protection,and can completely replace the traditional steel formwork, wood formwork, square wood, What's more, its amortization cost is very low.

PP Plastic Construction template board also called PP hollow form-work

1)Which is made of modified PP powder with other additives by heating and extruding.

2)Which has high reuse times and water proof

3)Can replace traditional plywood. Eco friendly and easy to assemble.

4)Plastic Construction Form-work is a style of building concrete structures with reusable plastic molds. This method requires almost no labor skills, gets the job done in record time, with minimal wastage in the process.

Machine list (PP Hollow Sheet Board Construction Formwork Building Template Extrusion Line Single Screw Plastic Extruder Machinery)

| Item | Name | Qty |

| 1.1 | Extruder | two sets |

| 1.2 | Mould | one set |

| 1.3 | Calibration Unit | one set |

| 1.4 | Haul-off machine | one set |

| 1.5 | Cooling bridge | one set |

| 1.6 | Cuuter | one set |

PP hollow construction formwork machine

The PP building templates extrusion production line is successfully developed by our company to absorb and digest foreign advanced extrusion technology and independent innovation. The plate thickness range can be made to 8-18mm, and the plate width can be customized according to customer's requirements of 915mm-1220mm. Its production surface is smooth and clean. , Small size error, with nail, planing, corrosion resistance, flame retardant and many other advantages.

PP Hollow Building Construction Template Board Extrusion Line PP Hollow Formwork Board Extruder Making Machine

Advantages

1. Light weight, high strength, high hardness, impact resistance, wear resistance.

2. Surface is smooth, bright and clean;Concreting and forming effect is good for pp hollow sheet making machine.

3. No absorption of moisture, no deformation, no mildew;Long-term immersion stratification in the water, no bubbles, sheet size stability, especially suitable for underground and dampenvironment.

4. Good toughness. pp hollow sheet making machine could be used as cambered special-shaped formwork.

5. Acid and alkali resistance, corrosion resistance; pp hollow sheet making machine is very suitable for the engineering application in coastal areas, mine, as well as seawall. pp hollow sheet making machine needs not do any preservative treatment both in using and storing the formwork, which do not pollute the concrete surface. 6. The reusable time for pp hollow sheet making machine can reach more than 60 times, long service life.

7. Waste products can be recycled and reprocessed, making full use of waste materials. This property can greatly reduce the project cost compared with wooden formwork and bamboo formwork.

8. Environmental protection and energy saving, no pollution. No any poisonous or harmful gas.

9. Demould easily. No need brushing release agent, only tapping, the plywood formwork price will fall off. Shorten working hours and speed up the construction schedule efficiently.

10. Easy to process. Sawing, drilling and nailing are all available. pp hollow sheet making machine can be combined vertically and horizontally optionally.

11. Easy to remove. Removing is convenient, quick and safe, and the supporting is also easy to operate,advantageous to the organization construction, effectively improving the construction schedule.

Main Technical Specification

| Model | SJ120 | SJ150 |

| Material | PP Modified Material | PP Modified Material |

| Products width | 915/1220mm | 915/1220,915×2 |

| Products thickness | 15-20mm | 15-20mm |

| Extruder specification | 120/3575/35 | 150/3590/35 |

| Capacity(Max.) | 350-450kg/h | 500-600kg/h |

PP construction template building formwork PP hollow board extrusion

PLASTIC PE PP construction template building formwork extrusion machine

PE PP construction template building formwork production line

PE PP plastic formwork board making machine

HIGHER OUTPUT

LOWER ENERGY CONSUMPTION

REASONABLE PRICE

I. Main introduction

Bringing in international advanced technology,combined with our practical experience and domestic requirement,this production line has been designed and developed by ourselves and is used to produce plastic sheet,according to different customers requirement,it can produce PVC,PP,PE,PS,ABS, pc, etc.

| model |

915/1220 |

|

| Suitable material |

|

PP/PE |

| Max .width of product |

mm |

915/1220 |

| Thickness of product |

mm |

16/18 |

| Extruder capacity |

Kg/h |

300-500 |

| Installed capacity(approx) |

kw |

350 |

| Dimension (L*W*H)(approx) |

m |

35*2.5*2 |

| Total weight(approx) |

t |

10 |