|

Project name

|

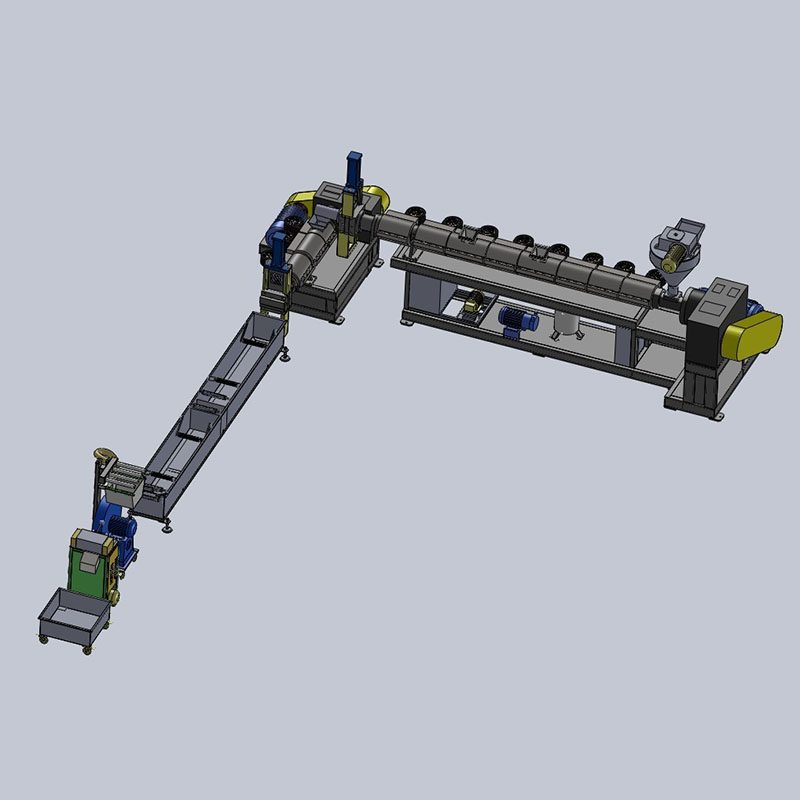

1000kg/hr PP PE film/jambo bag washing line

|

| Summarize

1. Electricity power use :380V,50Hz,3phase

2. Material: waste PP PE film , PP woven bag and etc

3. Final size of scraps: mesh screen: φ60mm

4. Output: 1000Kg/hour |

|

No

|

Equipment name

|

Technical parameter |

Qty.

|

| 1 |

Belt conveyor |

This machine mainly used to convey the PE/PP film into Plastic crusher

1. Motor power: 3KW ,Speed control by frequency inverter

2. Width of convey belt :1000mm

3. length of convey belt : 7000mm

4. Install isolation stick against-slide on the surface of the belt.

5. Adjust Height of conveying belt freely.

6. Small moving wheels are flexible and convenient.

7. the convey speed is adjustable which control the feeding production capacity per hour of the whole line

Note that you can put this convey under ground of the floor |

1set

|

| Metal detector |

Detecting ferrous and non-ferrous metals automatically

Width: 1000 mm

precision of metal detector: 1-3mm

Power: 0.55kw

|

1set

|

| 2 |

GL1000 Double shaft shredder |

1. Model : GL1000 Double shaft shredder

2. Application :PP/PE film and PP Woven bag and so on

3. feed mouth : 1200*1000mm

4. Diameter of rotator: 400mm( a pairs of rotator)

5. rotary speed of the main rotator: 82rpm

6. blade material :SKD-11

7. Wall thickness of shredder chamber: 30mm

8. Qty of rotary blade: 64pcs for one rotator (total of rotary blade: 64pcs*2set=128pcs)

9. Qty of fixed blade: 8pcs

10. Main motor: 45kw (45kw*2set=90kw)

11. production capacity : more than 1250kg/hour

12. brand of bearing : NSK Bearing

13. brand of gearbox : Red-sun brand or other famous brand

14. PLC brand : Siemens brand

15. Contactor and relay : Siemens brand |

1set

|

| 3 |

Belt conveyor |

This machine mainly used to convey the PE/PP film into Plastic crusher

1. Motor power: 2.2KW

2. Width of convey belt :900mm

3. Install isolation stick against-slide on the surface of the belt.

4. Adjust Height of conveying belt freely.

5. Small moving wheels are flexible and convenient.

6. the convey speed is adjustable which control the feeding production capacity per hour of the whole line |

1set

|

| 4 |

PC1200 Plastic Crusher |

This machine will crush the PE/PP film

1. Motor power: 75kw

2. Mesh screen:φ60mm

3. Rotation diameter of Main shaft: φ550mm

4. length of main shaft:1950mm

5. Feeding inlet: 1200mm×900mm

6. Quantity of rotating blade:10pcs(5group)

7. Quantity of fixed blade:4pcs(two group)

8. Crushing with water, the bearing with water cooling design

9. Capacity: 1000Kg/hour

10. Plastic crusher will work with water process

11. the screen exchange open ways : by motor drive

12. the hopper of crusher open ways : by motor drive: 1.5kw |

1set

|

| 5 |

Double Screw feeder |

This machine will used to send the film scraps into the next step

1. Effective length:3500mm

2. Screw diameter: φ380mm(double screw design)

3. Capacity: >1000 kg/hour

4. Motor power:3kw*2set=6kw

5.Material for contact with material: Stainless steel 304

6. This machine with water spray nozzle

Note that: 1. the angle will be 60 degree , it can help water in fast ways drainage .

2. for bottom parts will be with 2 meter in length for screen mesh to take dirty water as more as possible |

1set

|

| 6 |

High speed friction washer |

This machine is mainly used to clean the dirty on the surface of film scraps

1. Effective length: 3500mm

2. Motor power: 45Kw

3. Rotating speed: 1440rpm

4. Rotation diameter of main shaft: φ600mm

5. The thickness of screen mesh : 3mm

6.Material for contact with material: Stainless steel 304 |

1set

|

| 7 |

Screw feeder |

This machine will used to send the film scraps into the next step

1. Effective length:3500mm

2. Screw diameter: φ380mm(double screw design)

3. Capacity: >1000 kg/hour

4. Motor power:3kw*2set=6kw

5.Material for contact with material: Stainless steel 304

6. This machine with water spray nozzle

Note that: 1. the angle will be 60 degree , it can help water in fast ways drainage .

2. for bottom parts will be with 2 meter in length for screen mesh to take dirty water as more as possible |

1set

|

| 8 |

Hot washer |

This machine is mainly used to hot wash for PP/PE film

1. Effective length: 6000mm, Width: 1800mm

2. Washing roller motor: 2.2KW+3kw

3. Screw Feeding motor: 2.2KW

4. Qty of pushing roller : 5set

5.Material for contact with material: Stainless steel304

6. The floating washing tank with water level control device

7. The floating washing tank with automatic dirty discharge motor : 1.5kw

8. The diameter of discharge pipe : 159mm

9. Heating ways : we suggest by steam or hot oil heating |

1set

|

| 9 |

Screw feeder |

This machine will used to send the film scraps into the next step

1. Effective length:3500mm

2. Screw diameter: φ380mm(double screw design)

3. Capacity: >1000 kg/hour

4. Motor power:3kw*2set=6kw

5.Material for contact with material: Stainless steel 304

6. This machine with water spray nozzle

Note that: 1. the angle will be 60 degree , it can help water in fast ways drainage .

2. for bottom parts will be with 2 meter in length for screen mesh to take dirty water as more as possible |

1set

|

| 10 |

High speed friction washer |

This machine is mainly used to clean the dirty on the surface of film scraps

1. Effective length: 3500mm

2. Motor power: 45Kw

3. Rotating speed: 1440rpm

4. Rotation diameter of main shaft: φ600mm

5. The thickness of screen mesh : 3mm

6.Material for contact with material: Stainless steel 304 |

1set

|

| 11 |

Double Screw feeder |

This machine will used to send the film scraps into the next step

1. Effective length:3500mm

2. Screw diameter: φ380mm(double screw design)

3. Capacity: >1000 kg/hour

4. Motor power:3kw*2set=6kw

5.Material for contact with material: Stainless steel 304

6. This machine with water spray nozzle

Note that: 1. the angle will be 60 degree , it can help water in fast ways drainage .

2. for bottom parts will be with 2 meter in length for screen mesh to take dirty water as more as possibleNote that: 1. the angle will be 60 degree , it can help water in fast ways drainage .

2. for bottom parts will be with two meter in length for screen mesh to take dirty water as more as possible |

1set

|

| 12 |

Floating washer |

This machine is mainly used to clean the rest dirty on the surface of film scraps

1. Effective length: 8000mm, Width: 1800mm

2. Washing roller motor: 2.2KW+2.2kw+2.2kw

3. Screw Feeding motor: 2.2KW

4. Qty of pushing roller : 7set

5.Material for contact with material: Stainless steel304

6. The floating washing tank with water level control device

7. The floating washing tank with automatic dirty discharge motor : 1.5kw

8. The diameter of discharge pipe : 159mm

The bottom of screw feeder will two meter mesh screen |

1set

|

| 13 |

Screw feeder |

This machine will used to send the film scraps into the next step

1. Effective length:3500mm

2. Screw diameter: φ380mm

3. Capacity: >500 kg/hour

4. Motor power:3kw

5.Material for contact with material: Stainless steel 304

6. This machine with water spray nozzle

Note that: 1. the angle will be 60 degree , it can help water in fast ways drainage .

2. for bottom parts will be with 2 meter in length for screen mesh to take dirty water as more as possible |

2set

|

| 14 |

Dewatering machine |

This machine mainly used to dewater for film scraps to get final good quality film scraps

1.Motor power: 55KW

2.Capacity : 500kg/hour

3. Motor speed: 1440rpm

4. The diameter of the screen hole: 2mm

5. The thickness of screen mesh : 6mm

6. The dewatering rate: more than 95%

7. Continuously discharge the material from side and drainage from the bottom of this machine

8. Material for contact with material: Stainless steel304

9. Motor of Auto-brushing clean system :2.2kw

10. The material of Main shaft :stainless steel :diameter 220*8mm(Thickness)

11. The material of blade :stainless steel ,thickness:6mm

12. Rotation Diameter of main shaft: 800mm |

2set

|

| 15 |

Hot air drying system and air blower |

This machine is mainly used to use hot air to remove the moisture from PP/PE scraps

1.Total length of stainless steel pipe : 18meter

2.The diameter of stainless steel pipe : 219mm

3.Heating power of heating box : 45Kw

4.The temperature is adjustable by temperature controller

5. The Moisture of PP/PE will be less than 5%

6.Power of air blower motor: 11Kw |

2set

|

| 16 |

Silo |

This machine is mainly used to store the PE/PP scraps for next step packing

1. Effective volume: 4 m3

2. Tube diameter:Ф273mm

3. Material : stainless steel 304

4. motor of screw feeder:3kw |

2set

|

| 17 |

Control cabinet |

Electric elements: Schneider Contactor, Schneider Relay,

Inverter will use ABB brand or Danfoss brand |

1 set |

| 18 |

Blade sharper |

This machine is easy to operation ,just fix the blade on the machine ,and start the power

max sharping length : 650mm

motor :1.1kw

dimension: 1150*590*1320(mm)

weight : 150kg |

1 set |