PPR Pipe extrusion line ppr Fitting For Hot And Cold Water for injection mould

Qingdao cuishi plastic machinery since 1999 to make the high speed ppr pipe extrusion machine and we can make the pipe diameter with 16mm,20mm,25Mm 32Mm 40Mm 50Mm 63Mm 90Mm 160Mm 4 6 Inch 20Mm Germany Plumbing Hot Water Pipe Price Pn2.5 S5 Ppr Pipe

THE MACHINE TEST VIDEO :

|

Cold water PN1.25Mpa S5 PPR Pipe |

Cold water PN1.6Mpa S4 PPR PPR Pipe |

Hot water PN2.5Mpa S2.5 PPR Pipe |

Hot water PN2.0Mpa S3.2 PPR Pipe |

Steel Plastic Pipe |

Aluminum Plastic Pipe |

Steady-state control pipe |

||||

|

Size (mm) |

Thickness (mm) |

Size (mm) |

Thickness (mm) |

Size (mm) |

Thickness (mm) |

Size (mm) |

Thickness (mm) |

Size (mm) |

Size (mm) |

Size (mm) |

|

|

|

20 |

2.3 |

20 |

3.4 |

20 |

2.8 |

20 |

20 |

20 |

|

25 |

2.3 |

25 |

2.8 |

25 |

4.2 |

25 |

3.5 |

25 |

25 |

25 |

|

32 |

3.0 |

32 |

3.6 |

32 |

5.4 |

32 |

4.4 |

32 |

32 |

32 |

|

40 |

3.7 |

40 |

4.5 |

40 |

6.7 |

40 |

5.5 |

40 |

40 |

40 |

|

50 |

4.6 |

50 |

5.6 |

50 |

8.3 |

50 |

6.9 |

50 |

50 |

50 |

|

63 |

5.8 |

63 |

7.1 |

63 |

10.5 |

63 |

8.7 |

63 |

63 |

63 |

|

75 |

6.9 |

75 |

8.4 |

75 |

12.5 |

75 |

10.3 |

|

|

|

|

90 |

8.2 |

90 |

10.1 |

90 |

15.0 |

90 |

12.3 |

|

|

|

|

110 |

10.1 |

110 |

12.3 |

110 |

18.3 |

110 |

15.1 |

|

|

|

|

160 |

14.6 |

160 |

17.9 |

160 |

26.6 |

160 |

17 |

|

|

|

20-63 mm diameter 3-layer cold and hot water/ PN10-PN25 mm thickness PPR polypropylene pipes for water supply

Plastic Tube Hose Production Line Plastic Extruders HDPE LDPE PP PPRC PE PPR Pipe Making Machine

Machine TEST VIDEO :

Process

PPR PE Raw material + additive → VERTICAL mixing →vacuum feeding machine →hopper dryer → single screw extruder → color code extruder → HIGH SPEED 25M.MIN mould and calibrator →vacuum forming machine → cooling tank → haul off machine → SERVO MOTOR cutting machine → discharging rack

PP-R PE Pipe Production Line

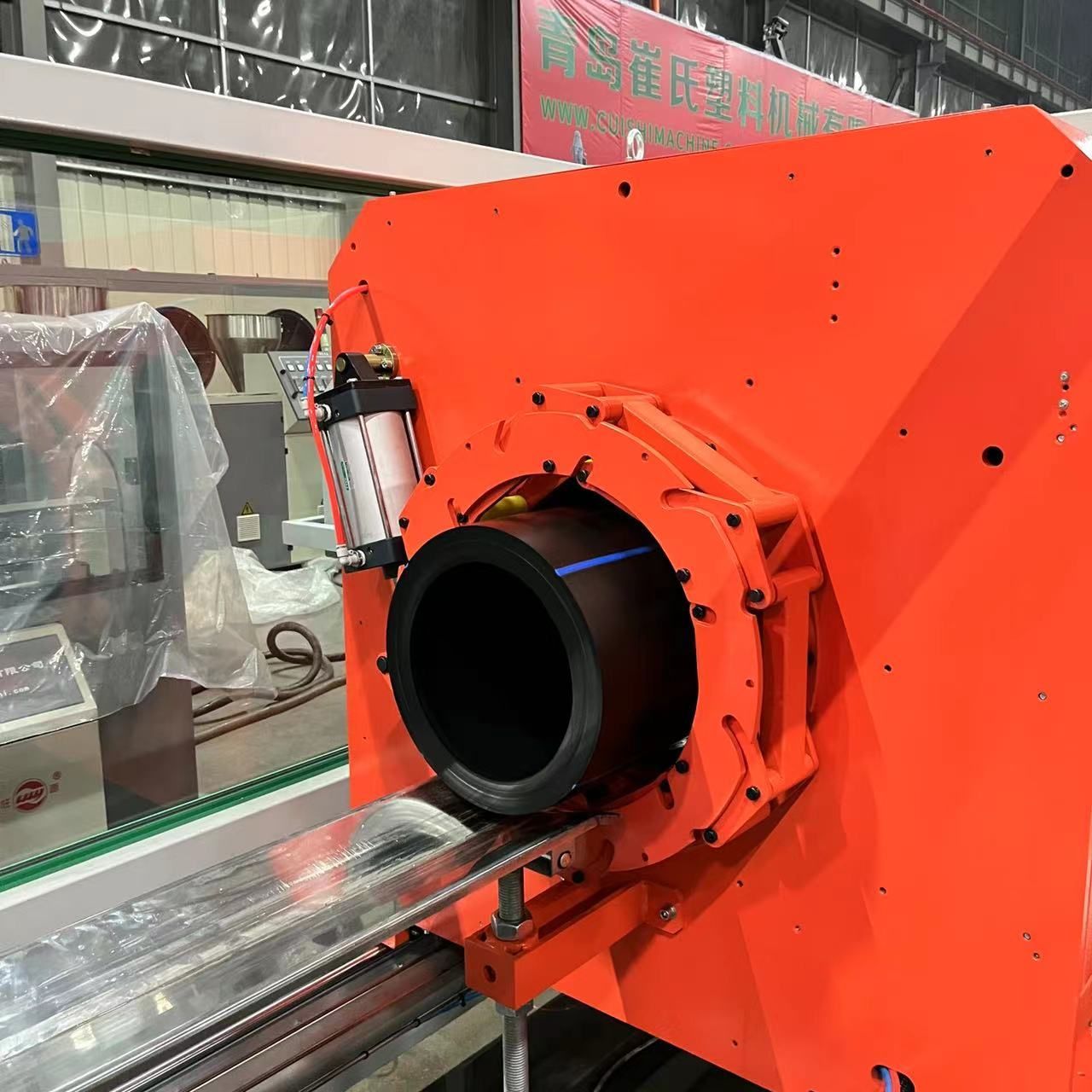

The PP-R PE pipe extrusion line is used to produce PPR pipe. Fiber glass PPR pipes with diameters from 20 to 160mm which are popularly used as hot and cold supply in civil water supply.

High efficiency PPR, PPRC, PP pipes are widely used in the uptown apartment and village cables protection, hot or cold water supplying, house heating system including flooring heating, wall heating and radiant, central air conditioning and industrial liquids transportation.

Application

1. PP-R Hot & Cold water supply pipe

2. Building heating system pipe, including flooring heating, wall heating and radiating system pipe

3. Central air conditioning system pipe

4. Industrial liquids transportation pipe.

5. Municipal water supply, water drain, gas supply pipe

6. Urban and rural drinking water pipelines

7. Agricultural irrigation pipe

8. Post and Telecommunications line pipe

9. Electrical Power cable wire protection pipe

10. Industrial liquids transportation pipe

11. Food and chemical industry pipe

|

Ф20-63mm PP-R Pipe Production Line |

|||

|

NO. |

Machine Name |

Model |

Qty. |

|

1. |

Auto-loader |

ZJ200 |

1 set |

|

2. |

Hopper Dryer |

75 KG |

1 set |

|

3. |

Single Screw Extruder |

SJ75/33, 55 KW |

1 set |

|

4. |

Co-extruder ( for marking line ) |

SJ25/25 |

1 set |

|

5. |

PP-R Pipe Mould |

Ф20- 110mm |

1 set |

|

6. |

Vacuum Calibration Tank |

Ф110x9m |

1 set |

|

7. |

Water Spray Tank |

Ф110x6m |

1 set |

|

8. |

Haul-off Machine |

2.2kw |

1 set |

|

9. |

No-dust cutter |

3kw SERVO MOTOR |

1 set |

|

10. |

Stacker |

4m |

1 set |

China High Performance Three Layers HDPE PPRC Pipe Making Machine 20-110mm pipe extrusion line

PPR pipe extruder: improve the production efficiency of PPR pipe

The use of plastic pipes is becoming more common in modern buildings because of their range of advantages such as corrosion resistance and ease of installation. Among plastic pipes, PPR (polypropylene random copolymer) pipes are widely used for their durability, temperature resistance, and low cost.

To meet the growing demand for PPR pipe, manufacturers need reliable and efficient production methods. A key factor in the production of PPR pipes is the PPR pipe extruder, which plays a vital role in converting raw materials into finished products. In this article, we will discuss the PPR pipe extruder and how it can improve the efficiency of the PPR pipe production line.

What is PPR pipe extruder?

PPR pipe extruder is a plastic extrusion machine designed to manufacture PPR pipes in various sizes and specifications. The machine is composed of extruder, die head, vacuum sizing tank, cooling tank, tractor and cutting machine. The extruder shapes and melts the PPR stock and delivers it to the die, which shapes the material into a pipe profile. The vacuum sizing tank and cooling tank cool and shape the pipe, while the tractor and cutting machine cut the pipe into the required length.

What are the advantages of PPR pipe extruder?

PPR pipe extruders offer several advantages over traditional PPR pipe manufacturing methods such as injection molding. A significant advantage is the ability to produce tubing in a continuous, high-volume fashion, reducing production time and costs. In addition, the extrusion process allows for more precise control over the diameter, thickness and quality of the pipe. It also eliminates additional processing steps, such as joining, which further reduces costs and simplifies installation.

How does the PPR pipe extruder improve the efficiency of the PPR pipe production line?

The efficiency of a PPR pipe production line depends on several factors including production rate, pipe quality and energy consumption. A PPR pipe extruder can significantly improve the efficiency of the production line in many ways:

Higher Throughput Rate: By using PPR pipe extrusion machine, manufacturers can achieve higher throughput rate due to the continuous production process of the machine. This means they can produce more pipe in less time, increasing production and revenue.

Improved pipe quality: PPR pipe extruders allow precise control of the extrusion process to produce pipes with uniform dimensions, smooth surfaces and fewer defects. This improves the quality of the pipe and reduces the need for rework or scrap.

Energy Efficiency: PPR pipe extruders are designed to be energy efficient and consume less electricity than other manufacturing processes. This translates into lower operating costs and a smaller environmental footprint.

Reduced labor costs: PPR pipe extruders require minimal labor compared to traditional manufacturing methods. This means manufacturers can reduce their labor costs and invest in other areas of their business, such as research and development or marketing.

In conclusion, PPR pipe extruder is a valuable tool to help manufacturers increase the efficiency of their PPR pipe production lines. With its ability to produce high-quality pipe faster and at lower cost, it is quickly becoming the method of choice for PPR pipe manufacturing. With the growing demand for plastic pipes, investing in a PPR pipe extruder is a smart decision for any manufacturer looking to remain competitive in the market.