Products

-

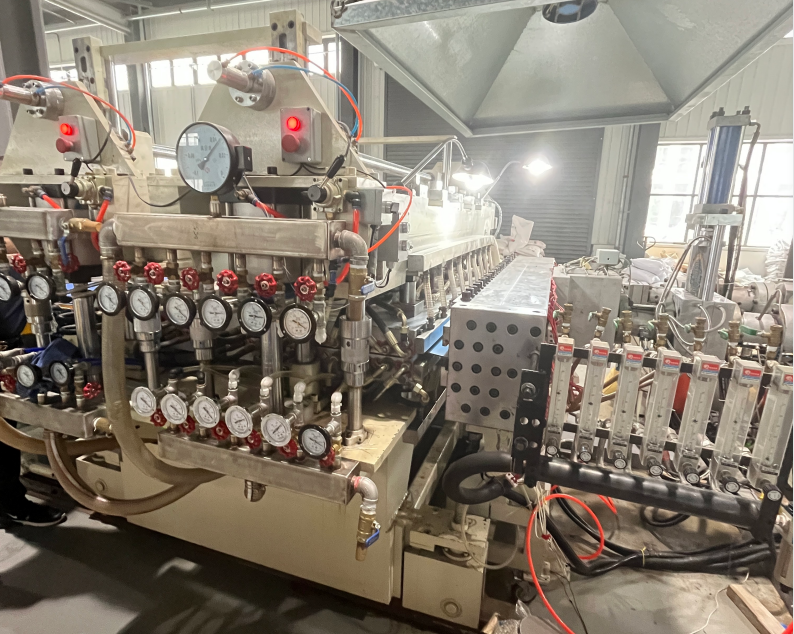

HDPE Spiral pipe extrusion line

Cod Multi Channeil Cable Bundle Pipe Extruder Extrusion Production Line

p...HDPE Bridge Plastic PP PE PVC Prestressed spiral Corrugated Pipe Extruder Die Head and Mold Machine

Plastic Cable Protection Spiral Pipe Machine HDPE Spiral Pipe Production Line

PE,PVC corrugated pipe production line manufacturing. The line could produce spiral corrugated pipe by HDPE or PVC raw materials.

This kind of spiral corrugated pipe is high temperature resistance, corrosion resistance, wear resistance, high strength, widely

used in bridge prestressed pipe, underground cable threading sheath, etc.

The machine inclued: double/ single screw extruder, die head mold, forming machine, cutting machine, winder system or

stacking machine. Product material is PVC/PE, optimal pipe diameter range for Φ 35-250 mm -

PPR Pipe extrusion line ppr Fitting For Hot And Cold Water for injection mould

Plastic PVC/PE/PP/PPR Single Wall Corrugated/Corrugation Electrical Conduit Protective Sheath Pipe Tube/Hose Extrusion Production Line

Application:PE Plastic Pipe Extrusion Line is mainly used in the production of agricultural drainage, water supply and cable conduit purposes. The unit consists of single extruder machine, mold, vacuum forming tank, multi-claw haul-off machine, planetary(chipless/non-dust cutter) cutting machine, stacker and so on. And the line can be equipped with Comptroller thickening instrument or computer ink-jet printer, etc. to achieve the production and manufacture of high-grade tubing.

Plastic Single Screw Extruder Double Three Triple ABA Layer PPR PE HDPE LLDPE LDPE Irrigation Water Supply Energy Gas Hose Pipe Tube Extrusion Production Line

Qingdao...PE Pipe Extrusion Machine Line/HDPE Pipe Production Line/Plastic HDPE/LDPE/PPR Electricity Conduit Tube/ Water Sewage& Gas Pressure Supply Pipe Line

-

plastic profile machine

Wood Plastic Composite PE PVC WPC Profile Decking Making Machine

Qingdao cuishi plastic machinery since 1999 , we are professional company specializing in the design and manufacture of plastic machines,such as single screw extruders, conical twin screw extruders, PVC, PE, PP and PP-R pipe extruders, PVC and WPC profile /board extruders,PVC and PE recycling machines, crushing,full biodegradable pelleting machines, and mixing machines for all kinds of plastics and other kinds of auxiliary equipment in the field.

Plastic Twin Double Screw Extruder PVC Wall Ceiling Panel Profile Extrusion Production Line

The production line consists of control system, conical twin screw extruder or parallel twin screw extruder,extrusion die, calibration unit,haul off unit, film covering machine and stacker.

-

PP PE Film Washing Line

Nowadays PET recycling technology is a most mature and common case among all polymers. Recycled PET can be used again to produce PET-based plastic products, e.g. bottles (not food & beverage-grade), fiber/cloth, sheet, strap band and, etc. This recycling chain not only reduces the pollution to your environment but also reduces production cost.

washing machinery

Project evaluation

According to your demand for PET recycling business, we’d like to recommend our standard PET bottle washing line with an output capacity of 1000kg/hr. This recycling line is composed of garbage separation (automatic and manual separation), crushing, continuous washing and dewatering & drying parts. Please check the below information:

2.1 Material characteristics

The material to be treated is PET bottles with contamination of:

- Labels

- Residues of original bottle content

- Metal, dust or sand accumulated during transportation or permanence in air

- PE plastic cups (PVC bottles, Aluminum caps are not accepted)

The materials can be in bales or loose, the operators should open the bale before introducing material into the line.

Finished product: clean PET flakes

... -

PP PE net pipe machine

PE HDPE plastic hard mesh pipe tube/ Sewage treatment biological packing network tube extruder machine

PE Pipe Production Line

PE Pipe Making Machine

Double Wall Single Wall HDPE PE PPR Plastic Pipe Extrusion Line

PPR Pipe Making Machine

PPR Pipe Extruder

Plastic PE PP Pipe Extrusion Production Line

Extruder

Double-Screw Extruder

HDPE PE PPR Pipe Production Line

PE Pipe Production Line

PE Pipe Manufacturing Machine

Wholesale Plastic Conduit Gas Water Irrigation LDPE HDPE PE Tube Hose Pipe Extrusion Production Line

Plastic Machine

Plastic Extruder

Plastic PP/PE Pipe Extrusion Line

Pipe Line

Extrusion Line

PE Huge Calibre Hollow Wall Pipe Production Line

Plastic Machine

Plastic Machinery

Single Screw PE Pipe Processing Equipment /PE Hot Melt Pipe Machine Production Line

Tube Extruder

Pipe Production Line

Cosmetic PE Tube/Hose/Pipe Extrusion Production Line

Multiple-Layer Extrusion PE Tube Production Line

Extrusion Tube Production Line for Cosmetic

High Qualitycustomized PE Plastic Pipe Making Machine Gas Pipe Production Line Made in China

Pipe

Machine

PP PE HDPE Corrugated Wall Flexible Hose Produce Machine Single Wall Corrugation Pipe Making Line

Plastic Corrugation Hose Extruder

Electirc Wire Flexible Conduit Making Machine

... -

plastic pipe elbow /pvc elbow /pipe fitting injection mould

Manufacturer High Precision ABS Plastic Injection Molding Custom Plastic Injection Mould for Plastic Parts

Injection Mould Plastic Injection Mould

Electronics PC/TPU/TPE/Silicone Material Molding Mobile Phone Case Plastic Injection Mould

Plastic Moulds Plastic Injection Mould

Customized Plastic Mold Tooling Mould Plastic Spare Parts Plastic Injection Moulds

Injection Moulds MouldsInjection Mold Plastic Mould Plastic Molds

1. We ... -

Plastic Pipe Making Machine/Single Wall Corrugated Pipe Extrusion Line/Single Wall Pipe Production Line From China

PVC-U double wall corrugated pipe UPVC communication corrugated pipe light and smooth anti-aging

110PVC communication corrugated pipe has very outstanding low temperature resistance

pvc corrugated pipe power communication pipe buried drainage pipe PVC double wall corrugated pipe

pvc double-wall corrugated pipe pvc-u communication pipe SN4/SN8 diameter 110-500 5G communication pipe

Corrugated Pipe Corrosion Resistance

PE Pipe Production Lines as The Drip Irrigation Production Line Main Pipe Used for Agriculture Irrigation Equipment

Drip Irrigation Pipe Machine

Drip Irrigation Tape Production Line

Plastic Single Screw Extruder Double Three Triple ABA Layer PPR PE HDPE LLDPE LDPE Irrigation Water Supply Energy Gas Hose Pipe Tube Extrusion Production Line

Pipe Extruder

Plastic Machine

HDPE LDPE PP PE Pipe Extrusion Line

Mixing Conveying System

PVC Dosing Feeding Mixing

HDPE Pipe Extrusion Line PE Pipe Production Line

HDPE Pipe Extrusion Machine

HDPE Pipe Make Machine

Professional Manufacturer for PE Corrugated Pipe Making Machine Extrusion Line

PE Corrugated Pipe Extruder

PE Corrugated Pipe Making Machine -

PET sheet production line

PE Geomembrane Production Line/ Plastic PP PE PS Pet Sheet Board Extrusion Machine/Plastic Sheet Extrusion Line /Pet Sheet Roll Production Line

Plastic Board Making Machine

Plastic Sheet Extrusion Machinewaste bottle pvc sheet pet flakes washing recycling line

pet flakes washing recycling line

pet waste plastic recycling machine

Kairong PP PE PC PVC Pet Plastic Sheet Extrusion Line

Plastic Sheet Extrusion Machine

Plastic Sheet Making MachineCompetitive Price Pet Single Layer/Multi-Layer Sheet Extrusion Line /Production Line

Plastic Machine

Plastic MachineryPlastic Sheet Extrusion

PET she...

Pet Sheet Extrusion

Plastic Sheet Extrusion Line PP Pet Plastic ABS Sheet Production Line PVC Plastic Sheet Making Machine Plastic Sheet Board Extrusion Line

Plastic Sheet Production Line

Sheet Extrusion Line -

-

PVC pipe production line

pvc pipe extruder

63-160mm PVC Pipe Belling Machine Plastic Socket Pipes Machine Plastic Extruders

PVC Pipe Belling Machine

Pipe Socketing Production Machine

Conical Twin Screw Extruder for Plastic PVC CPVC UPVC WPC Pipe Profile Granule Making with Horizontal Gearbox

Double Screw Extrusion Machine

PVC Pipe Extrusion Machine

Durable PVC Pipe Machine Energy Saving PVC Pipe Extruder

Pipe MachineSingle Screw Extruder Factory Direct Sale PVC Pipe Extruder Plastic Pipe

Detail ...

PVC Pipe Machine Price

Plastic Pipe Extrusion Line

16mm-630mm Pipe Caliber Wall Thickness Pressure Customized PVC Tube Conical Twin Screw Extruder Plastic Machinery

Plastic Pipe Extrusion Machinery

Plastic Pipe Production Line

Plastic Extruder for PE/PVC Pipe Reticulated Pipe Production Line Extruder

PVC Extruding Machine

Extruding Machine

PVC Pipe Extrusion Machine New PVC Extruder Production Line for Pipes

Pipe Extruding Machines -

PP Hollow sheet line

PP Hollow Lattice Board Sheet Extrusion Production Line

Corruga...

PP Hollow Sheet Machine

PP Hollow Sheet Extrusion Line

PP Corrugated Sheet Extrusion Line/PP Hollow Sheet Extrusion Line

PP Hollow Sheet Extrusion Line

Plastic Box Sheet Production Line

New Generation PP Building Template Production Line PP Hollow Template Sheet Machine Production Line

PP Building Template Production Line

PP Sheet Machine Production Line

Hot Sale PP Hollow Sheet Making Machine Building Formwork Production Line

Building Formwork Production Line

PP Building Formwork

The Newest PP Hollow Fluted Sheet Extrusion Line

Lexan Sheet Extrusion Line

PP Sheet Extrusion Line

PC Sunshine Board/PP Hollow Sheet Extrusion Line

PP Hollow Sheet Extrusion Line

PP Hollow Sheet Production Line -