Products

-

-

-

PVC Foam Board Extrusion Machine

Extrusion Plastic PVC|WPC Wall Panel|Foam Board|Window Profile Screw Barrel Extruder Screw Barrel Extruder

Plastic Extruders China Professional Plastic ,PVC Foam Sheet Board Advertising Decoration Extrusion ,Extruder ,Plastic Foam Sheet Machine ,Plastic Crust Sheet Machinery

PVC Cabinet Board/Ambry Board Making Machine Plastic Foam Board Extruder Plastic Foam Sheet Machine Plastic Crust Sheet Machinery PVC Crust Foam Plate Machinery WPC Foam Board Extrusion Line / Extruder PVC Foam Board Making Machine PVC Foam Board Machine Celuka Technology Free Foam PVC WPC Plastic for Interior Decoration Board Extruder Plastic Mache

PVC Foam Board Making Machine

Produc...

PVC Foam Sheet Making Machine -

pp pc hollow grid sheet extrusion machine

P hollow corrugated sheet extrusion machine can produce the sheet with the width of 1220-2800 mm.

With continuous improvement in the field of hardware and software, new and optimized electronic control system, original designed fast cooling and calibrating design, high-precision haul off and cutting control, Tongsan PP corrugated hollow sheet machine has the advantages of stably production, high efficiency, superior quality of finished product, wide adaptability of raw material.The plastic hollow sheet is eco-friendly new material in the market.it has the advantage of non-toxic, no smell, pollution-free, water-proof, anti-moisture, corrosion resistance, light weight, tough-resisting, thermal shock proof, economy and durability, rich colors etc, It also has the properties of flexural resistance, tensile resistance and high strength etc.

PP PC ...

The plastic hollow sheet is widely used in advertisement, interrior decoration, transportation and package for machinery, electron, home appliance, medicine, food, glass, agricultural products.

The PP hollow sheet corrugated box is new packing material in the market, it can be manufactured with different size and shape, it is ideal packing material for replacing the paper box and calcium plastic box.

The PP hollow sheet is reusable and 100% recyclable, and there is non-pollution in production, it is environment-friendly products which is widely proposed. The paper industry causes environment pollution and the production cost is going up higher and higher.

With the vigorous development of e-commerce, the market demands of packing box is bigger and bigger, the future logistics packaging requires light weight、economic and environment-friendly packing material, the plastic hollow sheet completely conforms to this concept, so the plastic hollow sheet has a broad development prospect. -

CS200 PVC PE pipe Tube threading machine

PVC Casing and Slotted Well Pipe Grooving Machine slotting machine has a threading capability of 2″ up to 10″ PVC Pipe.

Thread... -

CS63-200mm PVC pipe grooving socketing machine

Pvc/pe seepage pipe corrugated pipe full-automatic slotting machine.

Pipe d... -

Plastic corrugated pipe machine

plastic single wall corrugated pipe extrusion line can produce PP/PE/PVC/EVA/PA corrugated pipe.Mould Chain adopts gear transmission,base plate adopts water cooling,mould adopts air cooling.

Corrugated Optic Duct / Cod Pipe Tube Making Single Screw Extrusion Extruder Machine

plast...

Pipe Production Line

Plastic Pipe Machine

Bridge Culvert Helix Pipe Extrusion Line 2000 Meter Length/HDPE Carbon Spiral Corrugated Pipe Extrusion Machine

Pipe Extrusion Line

Pipe Extrusion Machine

Cod Cable Protection Plastic Pipe Making Extrusion Machine

Pipe Extruder Machine

Pipe Machine

Flexible Pipe Plastic Extrusion Machine

PVC Garden Pipe Making Machine

PVC Soft Pipe Machine

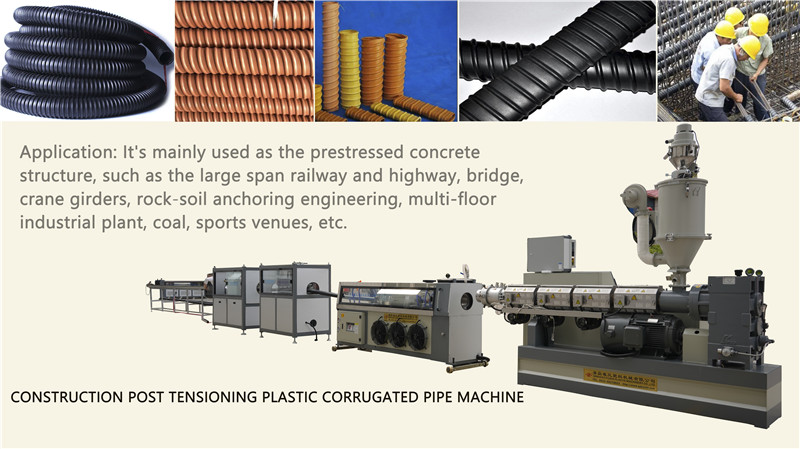

Prestressed Pipe Extruder Plastic HDPE PE Pipe Building Material Manufacturing Machine

Plastic Machine

Pipe Extrusion Line

PE HDPE Carbon Spiral Reinforcing Pipe Equipment Plant Extruder Extrusion Line Production Making Machine -

PP hollow sheet line

PP Hollow Lattice Board Sheet Extrusion Production Line

&n...

PP Hollow Sheet Machine

PP Hollow Sheet Extrusion Line

PP Corrugated Sheet Extrusion Line/PP Hollow Sheet Extrusion Line

PP Hollow Sheet Extrusion Line

Plastic Box Sheet Production Line

New Generation PP Building Template Production Line PP Hollow Template Sheet Machine Production Line

PP Building Template Production Line

PP Sheet Machine Production Line

Hot Sale PP Hollow Sheet Making Machine Building Formwork Production Line

Building Formwork Production Line

PP Building Formwork

The Newest PP Hollow Fluted Sheet Extrusion Line

Lexan Sheet Extrusion Line

PP Sheet Extrusion Line

PC Sunshine Board/PP Hollow Sheet Extrusion Line

PP Hollow Sheet Extrusion Line

PP Hollow Sheet Production Line

Small Corrugated Box Extrusion Line/PP PE PC Hollow Sheet Corrugated Roof Sheet Production Line

PP Hollow Corrugated Sheet Making Line

PP Corrugated Sheet Extrusion Line

Ex-Factory Price PP Hollow Profile Sheet Extrusion Line

Pet Sheet Extrusion Machine

PP Hollow Profile Sheet

PP PE Plastic Hollow Board/Corrugated Sheet Extrusion Line

Plastic Machine

PP PE PC Hollow Sheet Extrusion Line -

PVC Marble Sheet production line PVC Sheet/Board Extrusion Line

Waterproof PVC Furniture Foam Board Machine Production Line

PVC Furniture Foam Board Production Line

Foam Sheet Machinery

Plastic PVC|WPC Wall Panel|Foam Board|Window Profile|Spc Wood Composite Floor Decking|Glazed Roofing Sheet Extruding|Extruder|Extrusion Line

Plastic Extruder

Plastic Extruders

1220mm Plastic Extruder Machine PVC Foam Board Extrusion Production Line

Plastic Machine

Plastic Extruder

PVC Foam Extruder Machine PVC Skinned Foam Board Production Line -

PVC foam board extrusion machine

Plastic PVC Free Foam Plate Extrusion Line

In...

Plate Extrusion Line PVC Plate Extrusion Line

PVC Building Template Foam Board Extrusion Machinery / WPC Foam Board Production Line

PVC Crust Foam Board Machine WPC Foam Board Production Line

PVC Advertisement Board Foam Sheet Production Line

PVC Sheet Extruder PVC Foam Board Extruder

Most Popular WPC Foam Board Making Machine / PVC WPC Foam Board Sheet Production Line

Plastic Machine Extrusion

WPC Door Board Production Line/WPC PVC Door Foam Board Extrusion Machine Line

WPC Door Extrusion Line PVC Hollow Board Extrusion Line

Plastic Foam Extrusion Machine PVC Free Foam Board Extrusion Line

Board Extrusion Line PVC Board Extrusion Line

Sjsz-80/156 PVC Crust Foam Board Building Formwork Production Line

PVC Crust Foam Board Production Line -

PE GEOMEMBRANCE SHEET LINE

HDPE LDPE LLDPE PVC EPDM plastic sheet fish farming pond tank geomembrane aquaculture farm geomembranes factory price

PE Geomembrane sheet machine

PE Geomembrane Plastic Sheet Extrusion Line

HDPE ...

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geomembrane Profile Sheet Extruder Machine

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geomembrane Sheet Extruder Machine

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geomembrane Profile Sheet Extrusion Line

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geogrid Extrusion Line

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geomembrane Polymer Sheet

Geogrid Extruder

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geogrid Extrusion

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Plastic Geogrid Extrusion Line

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geomembrane Profile Sheet Extrusion

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Geomembrane Sheet

Geogrid Extrusion Line

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Plastic Geogrid Extrusion Machinery

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line

PE Plastic Geogrid Extruder Line

PE Geomembrance Sheet Extruder

PE Geogrid Extrusion Line -

HDPE BOARD MACHINE

Polypropylene plastic PP Sheet/ board extrusion machine China Manufacture Hgigh Impact Strength PVC Rigid Sheet Door Panels Glossy Matte Surface Cladding Application PVC Sheet Display Board PVC Board Wall Panel Cabinets Board PVC Sheet Self Extinguish Parapets Door Panels PVC Boards Shop Fitting Weather Resistance China Manufacture Hgigh Impact Strength PVC Rigid Sheet Door Panels Glossy Matte Surface Cladding Application PVC Sheet Display Board PVC Board Wall Panel Cabinets Board PVC Sheet Self Extinguish Parapets Door Panels PVC Boards Shop Fitting Weather Resistance

...