PVC pipe production line

Detail Technical Parameters of Each Above machines

1. screw loader feeder

| 1 | Screw load pipe diameter | mm | Φ110 |

|

|

||

| 2 | Screw pipe length | mm | 4200 |

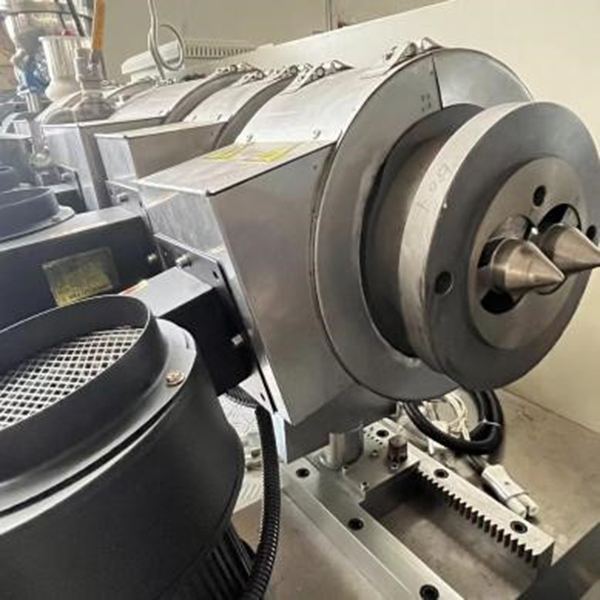

2. Conical twin screw Extruder SJSZ80/156

3. Mould for PVC pipe two sets

4,Vacuum Calibration and cooling Tank

5. Water spray cooling tank

6. Four pedrails haul off machine

7. Automatic planetary cutting machine

| Item | Description | Unit | Remarks |

| ﹡PLC control、automatic meter counting cutting, Planetary cutting

﹡Pneumatic clamping and releasing, Pneumatic cutting return ﹡Saw blade adopts carbide blade ﹡With dust colleting device |

|||

| 1 | Cutting type | mm | Automatic cutting |

| 2 | Cutting diameter suitable range | mm | 75-315MM |

| 6 | Material of Cutting Saw | Alloy steel | |

| 7 | Clamping Mode | Pneumatically | |

| 8 | Element of Electric System | mm | Schneider |

| 9 | Valve of Pneumatic system | From AIR TAC | |

| 10 | PLC TOUCH SCREEN | OMRON ,JAPAN | |

9. Stacker for finished pipe

Stacker

| Item | Description | |

|

||

| 1 | Tilting mode | Pneumatically drive automatically |

| 2 | Control mode | Automatic by sensor |

| 3 | Length | 4000mm |

| 10SHRL 500/1000 high speed heating/cooling mixer one set | |||

Screw loader machine ( send material to hot mixer )  |

|||

|

Heating mixer

|

Motor power | kw | 75 |

| Cover of boiler | one set made of alloy | ||

| Body of boiler | one set made of stainless steel | ||

| Mixing time | Min | 8-15 | |

| Lodicules &guiding board | one set | ||

| Air tank | one set | ||

| Working temperature | ≤150℃ | ||

| Air moving system | one set | ||

| INVERTER | 75KW | ||

| INVERT BRAND | MADE IN CHINA | ||

| Max out put | Kg/h | 720-920kg/h | |

|

|||

| Cooling mixer | Total motor power | kw | 11 |

| Body of boiler | one set made of stainless steel | ||

| Lodicules of water circling cooling | one set made of stainless steel | ||

| Running Water pressure | Mpa | ≥0.1 | |

| Electric equipment controlling set | one set | ||

| Controlling platform | one unit welded by steel | ||

| Cold mixing mixer volume | 1000L | ||

| Reducer model | WPO175 1:20 | ||

| Max out put | Kg/h | 720-920kg/h | |

|

|||

11.PVC pipe belling machine Full automatic

| Technical parameter: |

| l Model: SGK-315 |

| l Application ranger(mm): 75-315mm |

| l Axis height(mm): 1000-190 |

| l Fast hauling off motor(KW): 1.1 |

| l Lift motor power (KW): 1.1 |

| PLC XINJIE OR CHINA BRAND |

| Text famous brand of china |

| Temperature control meter famous brand of china |

| l Photoelectric switch famous brand of china |

| l Air-break switch Delixi |

| l Contactor Schneider of France |

| l Pneumatic components : Famous bran of china |

| l Air cylinder: china and Italy joint venture |

12. 600 PVC pulvertizer www.cuishimachine.com www.cuishiextruder.com

1、 According to the heat work equivalent: after doing work per hour into 860 kcal heat, this machine is external exhaust, the air volume is large, by the import and export of the wind temperature difference on behalf of most of the heat, a small part of the heat is solved by water cooling. Requirements: The inlet temperature of the cooling water is not more than 25, the outlet water temperature is not more than 50, and the cooling water flow is appropriately increased in summer to reduce the temperature。

13. SWP630 PVC Pipe Crusher

Electric cabinet system: The main accessories are Siemens or Schneider

- Number of moving knives: 6 pieces

- Number of fixed knives: 4 pieces

-- -Air delivery system:

+ Motor: 3Kw – Brand Red Flag

+ Volume of stainless steel air hopper: 100 cubic meters (liters)

14.PVC Pipe Thread Cutting Machine

200-315mm Automatic pipe internal and external thread machine

| 1 | type | CS-315 |

| 2 | Pipe diameter | ¢200mm/¢250mm/¢315mm |

| 3 | Pipe length | 3m,6m |

| 4 |

center height

|

1000mm |

| 5 |

Use voltage

|

380V, 50HZ,3phase |

| 6 |

compressed air pressure

|

0.6Mpa |

| 7 | Total power | 8KW |

| 8 | Main motor | 3KW |

| 9 | Forward motor | 0.75KW |

| 10 |

Dust fan power

|

3KW |

| 11 |

Lifting motor power

|

0.37KW |

| 12 |

height adjustment

|

Electric adjustment----by button

|

| 13 | Machine color | With customer need |

| 14 | Machine size | 8370*2250*2300 |

| 15 | Machine weight | 2800KG |

| 16 |

thread type

|

T-shaped external thread and T-shaped internal thread

|

| 17 | Blade material | W18Cr4V |

15 PIPE GROOVING MACHINE