Wholesale Price China Plastic Can Crusher - 300kg PE PP water ring pelletizing line – Cuishi

Wholesale Price China Plastic Can Crusher - 300kg PE PP water ring pelletizing line – Cuishi Detail:

PP PE film water ring pelletizer Line

| SJ120 pp, pe pelletizer line | ||

|

|

1.Auto feeder with hopper |

1set |

|

|

2. SJ120/30 Extruding machine |

1set |

|

|

3.High speed screen exchanger |

1set |

|

|

4.Water ring pelletizing machine |

1set |

|

|

5. Dewater machine |

1set |

|

|

6. Vibrator sieve |

1set |

|

|

7.Air blower |

1set |

|

|

8. silo |

1set |

|

|

9. Control cabinet |

1set |

300kg/hour PE PP Pelletizing line

General description:

1、Process material : Crushed PE,PP film or craps

2、Extruder Model: SJ120/30

3、production capacity : 300kg/hour

4、Pelletizing ways : Water-ring pelletizing way

5、Power supply: 3Phase/380V/50Hz

PART I Flow chart of PE PP pelletizing line

The process flow of PE PP pelletizing line as following:

Screw feeder →auto loader→ SJ120/30 Extruding system →High speed screen exchanging→ High speed screen exchanging and Mold → water pelletizing machine→ Dewater machine→ Vibrator sieve → air blower system → Silo

Part III Specification for each equipment

B.1 screw feeder 1 set

1. Effective Conveying Part: 3500mm;

2. Motor Power: 1.5KW

3. Diameter of screw feeder: 380mm

4. The material of screw feeder: stainless steel 304

B.2 Extruding Machine 1 set

1. Screw Diameter: φ120mm

2. Motor Power: 75kw, AC Motor

3. L/D: 30:1

4. Material of screw: 38CrMoAl

5. Screw barrel: 6kw×8 heating zone

6. Vacuum venting system: 1 section

7. The power of vacuum pump: 2.2kw

8. The gear box: special hard gear reducer:

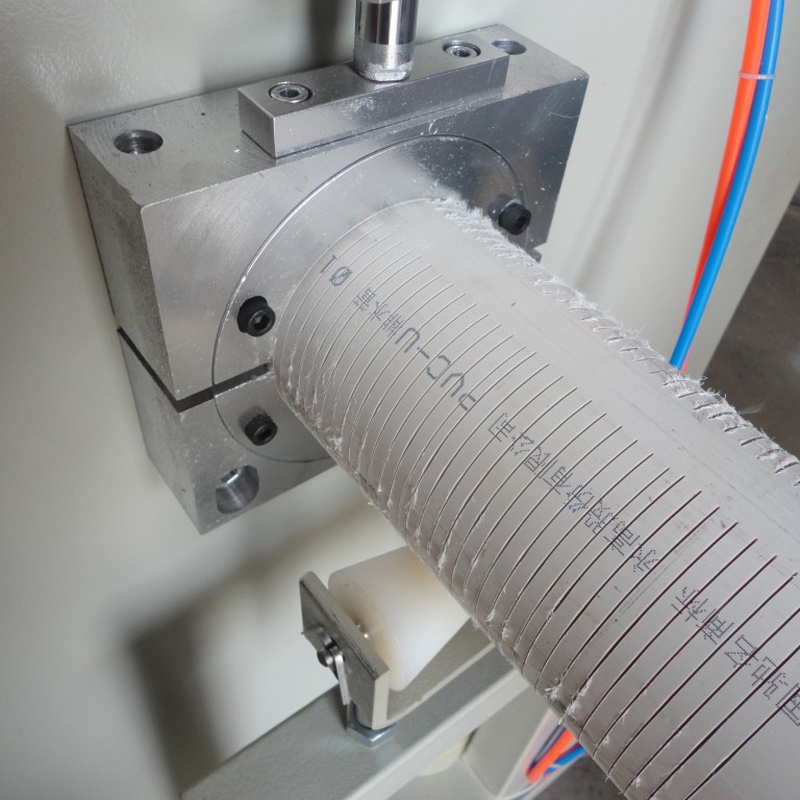

B.3 High speed Screen exchanging 1 set

1. No stop Hydraulic oil station device: 2.2kw

2. The time for changed Net<2 seconds

3. The system pressure: 16Mpa

4. Material: 40Cr

B.4 Water ring Pelletizing Machine 1set

1. The material of the blade: SKD-11

2. The power of the motor for granulating machine: 1.5kw

3. The palletizing speed: best brand in china Inverter Frequency conversion.

4. Rotate Speed: 1400rpm

5. The material contact with the material: stainless steel 304

B.5 Dewater Machine 1set

1. Power: 5.5kw

2. Rotate Speed: 1450rpm

3. Adopt down drainage

4. The material contact with the material: stainless steel 304

5. Power of water pump: 2.2kw, it is recycling the water for water-ring pelletizing head

B.6 Vibrating sieve 1set

1. The Power of the vibrating motor: 0.22kw

2. The material contact with the material: stainless steel 304

3. The machine is used to separate the un-normal shape of PP/PE pellet

4. The capacity: 300kg/hour

B.7 Air blower system 1 set

1. The power of the air motor: 4kw

2. The diameter of the pipe: 114mm

3. The material of the pipe: stainless steel

B.8 Silo 1set

1. Volume: 1.5 m3

2. The material of storage: stainless steel 304

B.12 Control cabinet for the whole line 1set

Siemens Contactor, RKC temperature control instrument, Made in Japan, Inverter Made in china best brand. Automatic warming system for power overflow and pressure overflow on the extruder.

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for Wholesale Price China Plastic Can Crusher - 300kg PE PP water ring pelletizing line – Cuishi , The product will supply to all over the world, such as: Islamabad, Borussia Dortmund, Germany, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

We have been looking for a professional and responsible supplier, and now we find it.